Stainless steel’s widespread use has transformed the metallurgical sciences. The factors at play are reshaping the fabrication industry. Stainless steel has always been the competent winning metal. Stainless steel is updated and used in a variety of manufacturing equipment, ranging from kitchenware to aerodynamics, healthcare, and construction. Its importance in numerous initiatives was recognised by innovative designers, engineers, and scientists. Its use is pirouette-like and speedy. Stainless steel is a large family with over 150 different grades. It’s a low-carbon alloy with a chromium content of at least 10.5 percent. The chromium oxide layer created by the addition chromium is inert. The chromium oxide layer is responsible for the majority of corrosion resistance and flawless finishing. Nickel, molybdenum, titanium, sulphur, and manganese are some of the other alloying agents that may be present.

Chemical composition influences the grading terminology. Chemical composition, in turn, determines mechanical properties. Significant physical and mechanical properties influenced the selection of an alloy for fabrication projects, stainless steel has a lot of advantages when it comes to fabrication operations, stainless steel is widely employed in a variety of industries. It possesses corrosion resistance, strength, and aesthetic appeal, among other qualities. Its advantages include coded and synchronised.

The following are some of the advantages of using stainless steel:

Corrosive Medium Resistant

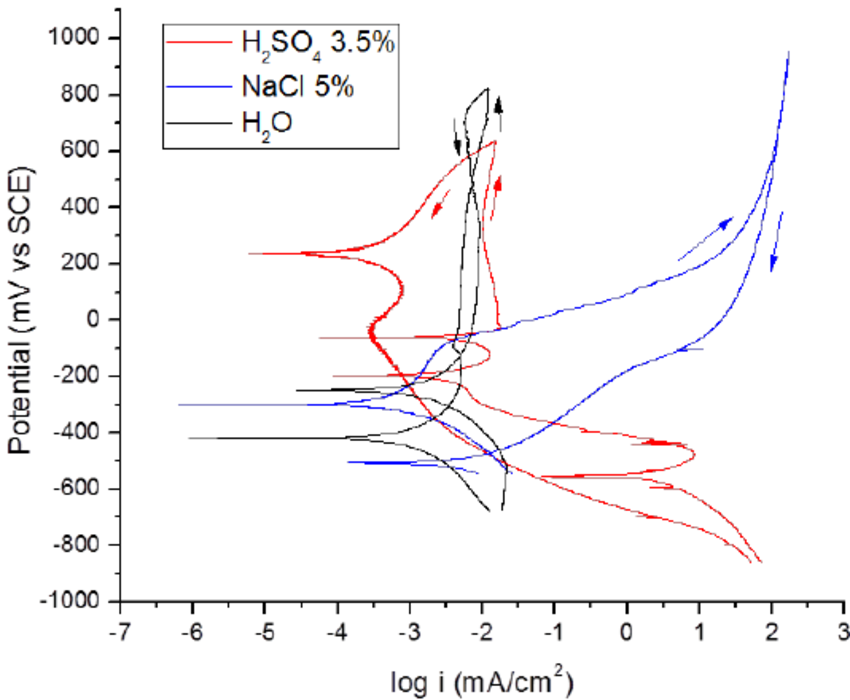

For extended life, the most important feature of stainless steel is that it is rust-free. It’s a better choice because of the corrosion protection feature. Stainless steel resists corrosion in a variety of environments, including acidic, alkaline, and chlorine environments. The amount of chromium in a material affects its corrosion resistance. Low alloyed grades work well in humid conditions and with water, but high alloyed grades function well in acidic, alkaline, and chlorine corrosion situations.

Fabrication Simplicity

Stainless steel is cut, welded, stamped, and tooled during the fabrication process. Fabrication may appear to be difficult. The typical machine may cause issues. Under professional supervision, stainless steel can be cut, weld, bent, machined, assembled, and simply produced using current machining and tools. Extensive precision machining using stainless steel grades opens up fabrication possibilities in a variety of tasks.

Strength

The strength of stainless steel, which is employed in a variety of industries, is a highly promising factor. It has natural strength and can withstand shocks at severe temperatures.

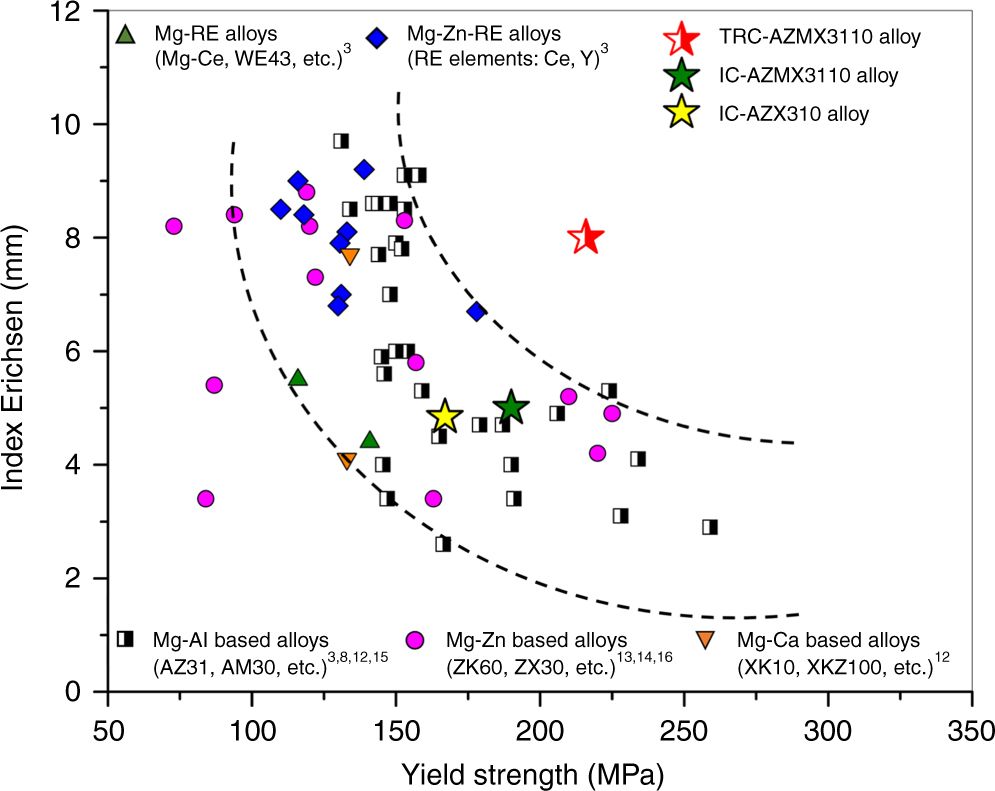

Ratio of strength to weight

Cold working can strengthen austenitic stainless steel, which has a high strength-to-weight ratio. Stainless steel is preferred in the aviation industry because to its excellent strength-to-weight ratio. Stainless steel is both environmentally friendly and remarkably long-lasting, stainless steel is a natural material that is recyclable, long-lasting, and environmentally beneficial. Old stainless steel scrap accounts for the majority of stainless steel production. It is well regarded and relieves stress on the environment.

Resistance to extreme temperatures

Stainless steel is extremely resistant to fire and heat. It has a high scaling temperature as well as a high scaling strength. In the manufacturing of heat exchangers, boilers, aircraft, and the petroleum industry, stainless steel is widely employed at cryogenic temperatures, stainless steel demonstrates exceptional strength.

Maintenance and Hygiene

Stainless steel has a high level of hygienic properties. Its flat surface prevents bacteria from breeding and is simple to sterilise and maintain. Stainless steel is in high demand in the food processing, medical, and pharmaceutical industries In-house ware appliances, as well as equipment.

Long –term use

Yet simple and effective measures can benefit the stainless steel in long run use. The production and fabrication cost seems to be more when compared to other steel options. But the result obtains for the long run is surprising and explanatory.

Aesthetic appearance

The bright shiny surface gives a beautiful pleasing effect and hence used in the architectural project. The lustrous example is stainless steel used in the concert hall of Walt Disney and Chicago cloud of USA.

Use for a long time and A pleasing appearance

Simple and effective actions, on the other hand, can benefit stainless steel in the long run. When compared to alternative steel options, the cost of manufacture and fabrication appears to be higher. However, the long-term outcome is both shocking and illuminating.

The brilliant, gleaming surface creates a lovely, appealing effect, which is why it was utilised in an architectural project. Stainless steel, for example, is utilised in Walt Disney’s symphony theatre and the Chicago cloud in the United States.

Stainless steel appears to be pricey for any job at times? Yes, it’s a tad. It does, however, come with a slew of engineering-related advantages. The long-term embedded approach to sustainability should be a priority for project designers.

To summarise, stainless steel is the clear winner in a variety of applications. Despite the fact that manufacture, professional knowledge, and high-quality equipment are all involved.

Read More

Some Little-Known Facts about the Metal Fabrication Process

How To Choose The Best Metal Fabrication Company

Recent Comments