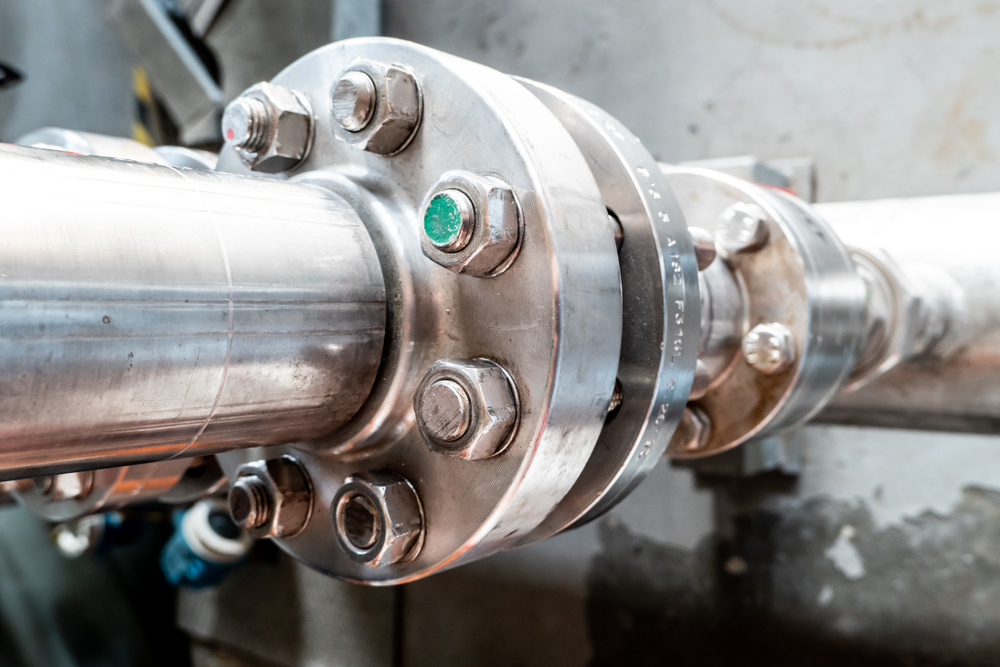

Flanges are used to connect many equipment such as valves, pipes, pumps etc, to make a pipework system, Generally flanges are threaded or welded, flanges are connected together by bolting them with gaskets to provide a seal that provides easy access to the piping system. Flanges give you more options when it comes to managing piping systems since they allow for easier disassembly and better access to system components. Following the ASME B 16.5 or ASME B 16.47 standard, piping flanges are chosen based on pressure-temperature ratings and pipe class. Custom-made pipe flanges, on the other hand, can be constructed but are not favoured in industries. Piping flanges are made by forging and are a better option to welding or threading. Slip on flanges, weld neck flanges, blind flanges, and socket weld flanges are just a few of the types of flanges available. The several types of flanges used in plumbing systems are detailed below based on their diameters and other criteria.

IBR FLANGES

IBR Flanges A pipe flange uses bolted connections and gaskets to connect piping and components in a plumbing system.Certain flanges, such as weld neck flanges and socket weld flanges, require stating the pipe schedule in addition to the pressure class. IBR Flanges means Indian Boiler Regulations, The material of this regulations includes grades, pressure classes, dimensions and other properties of flanges, The IBR approved flanges are used in Industrial systems, Automobile industry, Sewage systems, Food Processing, Plumbing etc.

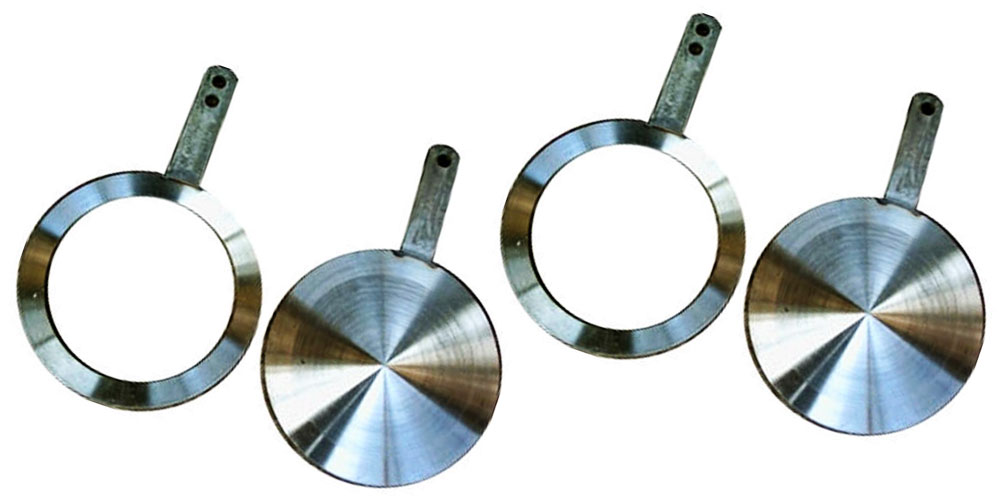

Spades & Ring Spacer Flanges

Spades & Ring Spacer Flanges are both similar to spectacle Blinds,but they both are not connected, They both are used in systems, where there is no need of maintenance but they are mostly used in large pipe size applications. Spades can weigh hundreds of pounds depending on the flange sizes and the stress level, In order to escape additional weight, the connection of flange is not choosen particularly for spectacle blind, but for both separate products higher maintenance of the pipe system can be an important reason for the replacement of Ring Spacer with a spade.

Orifice Flanges, Spectacle flanges

Orifice flanges are used in conjunction with orifice metres to determine the flow rate of liquids or gases in a pipeline. The orifice flange is machined with pairs of pressure “Tappings,” usually on two sides, immediately opposite each other. Orifice Flange Unions are developed and manufactured in accordance with the recommendations of the American Gas Association (AGA), the American Society of Mechanical Engineers (ASME), and the International Society of Automation (ISA). Orifice Flanges come in a variety of shapes and sizes, including the following: Corner tap orifice flanges, Raised Face weld neck orifice flanges, Raised Face slip-on orifice flanges, Ring-Type joint weld neck orifice flanges, A spectacle flange is a type of flange that consists of two metal discs joined in the middle by a short steel portion. Spectacle flanges, also known as spectacle blind flanges, are widely used on piping systems that must be split on a regular basis or where the flow must be stopped on a regular basis. A spectacle blind, sometimes known as a spec blind, is a safety device that is used to isolate a length of line or piece of equipment so that it can be inspected or removed from service. The blind differs from a valve in that it is a long-term or permanent isolation device.

Long Weld Neck Flanges

Long Weld Neck Flanges are primarily used in Oil and Gas industry for high pressure or in fluctuating temperature situations.The long neck guides the pipe into flange it offers strengthening that is not possible with a standard welded neck flange,The strengthening is quite essential for the safety of Industrial, commercial and residential high pressure systems.

Nipo Flange / Weldo Flange

A Nipoflange is a combination of Weldolet, nipolet and welding Neck flange which is widely used in Pipe Industry. A Weldo flange is designed like a weldolet on the run pipe side and on the other side it has flange coneection, It means the branch connection on the run pipe side is a welding connection, In a Nipo Flange the connection of branch on the run pipe side is a welding connection and a flange connection on other side.

Nozzle flange

Nozzle flanges are the most extensively used and important component in forming piping systems in a variety of industries Nozzle flanges are the most extensively used and important component in forming piping systems in a variety of industries. A flange is a round disc with a hole that connects pipes, valves, pumps, and other pieces of equipment. Flanges are suited for joining in the piping system and come in a variety of sizes.

Blind flanges

A blind flange is a solid flange, The main objective of this flange is to block off a section of pipe or a nozzle on a vessel that is not used. Blind flanges are used to close off the ends of pipe systems or the openings of pressure vessels. They are widely used to test the flow of gas or liquid through a pipe or vessel, as well as to provide quick access to the pipe in the event that work needs to be done inside it.

Socket weld flange

Smaller diameter high-pressure pipes are often fitted with socket-weld pipe flanges. Inserting the pipe into the socket end and applying fillet weld around the top is how these pipe flanges are joined. This results in a smooth bore and improved fluid or gas flow inside the pipe.

Threaded Flange

Threaded flanges are flanges with taper pipe threads in their bore that comply with ASME B1. 20.1 and can be used in piping systems where welding the flange onto the pipe is not possible, such as in highly explosive regions where welding poses a risk.

Lap joint flange

When the pipe is composed of a costly material, lap joint flanges are employed with the stub ends. For example, because the flange will not come into touch with the substance in the pipe, a carbon steel flange can be attached to a stainless steel pipe system. The flanges will remain unfastened and the stub ends will be butt-welded to the pipe. To clear the stub end radius, the inner radius of these flanges is bevelled. Threaded flanges are flanges with taper pipe threads in their bore that comply with ASME B1. 20.1 and can be used in piping systems where welding the flange onto the pipe is not possible, such as in highly explosive regions where welding poses a risk.

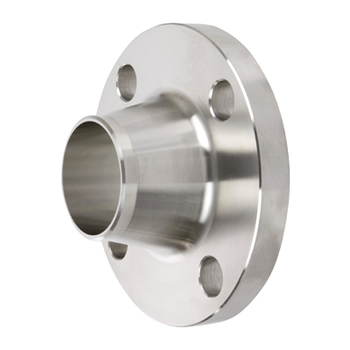

Weld Neck Flanges

A weld neck flange, also known as a tapered hub flange or a high-hub flange, is a type of flange that can transfer stress to pipes, reducing high-stress concentration at the flange’s bottom. There are two types of welding neck flanges: the first is used with wipes, while the second, longer kind is utilised with process plants rather than pipes. The weld neck flange is a circular fitting that extends beyond the circumference’s rim. These flanges, which are usually made of forging, are welded to pipes. The rim is drilled with several holes that allow the flange to be affixed to a bolted flange. Because of the structural valve, this design is significantly superior.

Slip On Flanges

Flanges and Slip On Flanges in Stainless Steel India is the home of the SORF A105. The ASME B16. 5 slip on flange has an inner diameter that is slightly larger than the pipe’s outer diameter. This flange refers to a ring that is attached to the pipe and extends from the pipe’s end.

Recent Comments