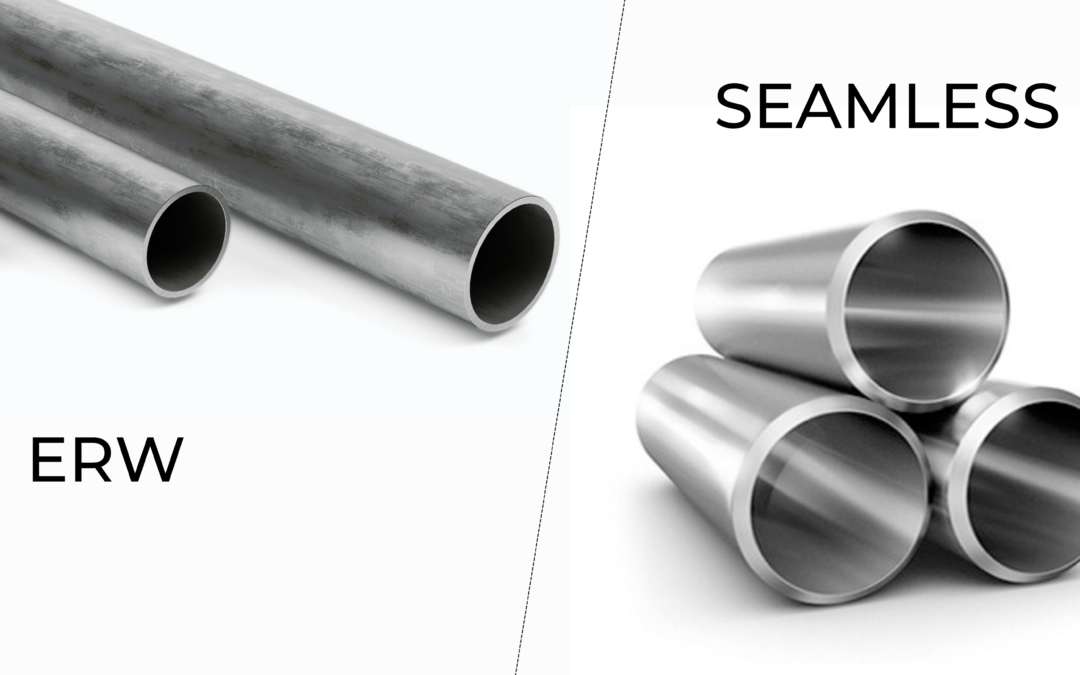

Rolling metal and then welding it longitudinally throughout its length produces Electric Resistance Welding (ERW) pipe. Seamless pipe is made by extruding metal to the necessary length, whereas ERW pipe has a welded junction in its cross-section throughout its length.

There are no welding or connections in the seamless pipe, which is made from solid round billets. In sizes ranging from 1/8 inch to 26-inch OD, the seamless pipe is completed to dimensions and wall thickness specifications. Hydrocarbon Industries & Refineries, Oil & Gas Exploration & Drilling, Oil & Gas Transportation, and Air and Hydraulic cylinders, Bearings, Boilers, and Automobiles are also examples of high-pressure uses, etc.

ERW (Electric Resistance Welded) pipes are longitudinally welded, made from a strip or coil, and have a diameter of up to 24 inches. ERW pipe is made by pulling a ribbon of steel through a series of rollers and forming it into a tube that is then fused with an electric charge. It is mostly utilized for low/medium pressure applications such as water/oil transportation. Pearlites Steel is a prominent manufacturer and exporter of ERW Stainless Steel Pipes in India. For further information on the product, please contact us.

ERW Steel Pipe is available in a number of sizes, from 2 3/8-inch OD to 24-inch OD, and in lengths up to 100 feet. Surface finishes come in both bare and coated varieties, and processing can be done on-site according to customer requirements.

The significance of ERW pipes has always been tainted by the fact that experts have previously indicated that they are weaker pipes than seamless pipes. Following the hot rolling methods, they are cold rolled, giving the ERW pipe greater corrosion and oxidation resistance. These pipes can be used in both high- and low-pressure systems. Plain, threaded, and beveled tubing ends are also available. These one-of-a-kind pipes can be easily customized in a variety of forms and sizes to meet your specific needs.

When investors use ERW pipes, they are seeking a low-cost solution that is also extremely reliable and can last for a long time without requiring substantial repairs. These pipes are simple to shape and machine. Experts and people in the piping business will continue to discuss the difference between ERW and seamless pipes. If you want to save money on these pipes, shop around.

Seamless or electric weld providing procedures are used on every carbon steel pipe constructed to API requirements, such as Casing pipe and Tubing pipe. There are numerous distinctions between seamless and ERW pipes. The key distinction is that Seamless Piping is manufactured with hot-working steel or, if necessary, cold-finishing the hot-worked product to get the desired shape, dimensions, and qualities. After welding, the welded seam of the electric weld pipe is either heat-treated to a minimum temperature of 1,000°F or processed to remove any untampered martensite.

If the electric-weld tube is heat-treated with the quenched-and-tempered procedure, which is required for API grades L80, C90, T95, and P110, such ERW disparities are usually resolved. Without the use of filler metal, the electric-welded pipe has one longitudinal seam generated by electric-induction or electric-resistance welding. The weld seam edges are physically forced together, and the heat for welding is generated by the welder.

Comparison of the Manufacturing process

The raw material is initially cast into ingots in both seamless and ERW techniques. The steel is then stretched out into a seamless tube or forced together and sealed with a weld to form a pipe. While it’s true that ERW pipe has a seam that makes it potentially weaker, providing techniques and quality assurance regimens have both evolved to the point that welded pipe will generally perform as required when tolerances aren’t exceeded.

While the obvious benefit is evident, one criticism of seamless piping is that the stretching and rolling process results in an irregular wall thickness when compared to the more accurate thickness of steel sheets going for welding.

Recent Comments