ASTM A182 Super Duplex Steel UNS S32760 Flange/ UNS S32760 Flange

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

UNS S32760 Flanges, Ferritic / Austenitic S32760 Plate Flanges, Super Duplex S32760 Flange, Super Duplex Steel S32760 Pipe Flanges, Super Duplex S32760 Flanges, ANSI B16.5 Super Duplex S32760 Flanges, ASTM A182 S32760 Flange, 1.4410 Flanges, Super Duplex 2507 Forged Flanges, Super Duplex steel S32760 Flanges, UNS S32760 Flange, Super Duplex S32760 Flanges Manufacturer in Mumbai, India.

Super Duplex Steel S32760 Slip-on Flanges, Super Duplex 1.4410 Socket weld Flanges, Super Duplex Steel S32760 Pipe Flanges, Super Duplex S32760 Threaded Flanges, Super Duplex S32760 Flanges, ASTM A182 Super Duplex S32760 Weld Neck Flanges, ANSI B16.5 Super Duplex Steel S32760 Flanges, Super Duplex Steel S32760 Flange Supplier in Mumbai, India.

Detailed Information

Prashaant Steel & Alloys is one of the most prominent manufacturers and suppliers of Super Duplex Steel UNS S32760 Flanges. Prashaant Steel & Alloys is the most popular manufacturer and exporter of Duplex Steel UNS S32760 Flanges to worldwide customers.. the low carbon content of Uns S32750 Flange, there is low risk or minimal risk of the occurrence of carbide precipitation at the grain boundaries during heat treatment. Hence, the ASME SA182 F53 Flanges is highly resistant to carbide-related intergranular corrosion, which is why many suppliers recommend using this stainless steel for a variety of operations. Duplex structure or the duplicity in the microstructure of the stainless steel grade 2507 provides these components an excellent resistance to chloride stress-related corrosion cracking or SCC. As compared to duplex stainless steel grade 2205, the UNS S32760 ASTM A182 F53 Pipe Flange offers superior properties such as corrosion resistance and increased tensile yield strength.

Another reason why buyers prefer using these components is that the wall size of the product or the cross-section of these fasteners can be reduced, thereby leading to a lightweight product. Besides being light in weight, the Super Duplex 2507 F55 Blind Flange is a cost-saving alternative due to its low consumption of the alloy during the manufacturing process. As the tensile yield strength is very high, lightweight products are not compromised in terms of their quality.

Super Duplex 2507 F55 Blind Flange applications include being used in equipment for industries such as chemical processing, petrochemical, and seawater. Super Duplex Stainless Steel Flanges tend to demonstrate excellent resistance to chloride stress-related corrosion cracking, a high thermal conductivity as well as a low coefficient of thermal expansion. The high content of chromium, molybdenum, and nickel in the ASTM A182 F51 Pipe Flange provides the flanges an enhanced or increased resistance to pitting, crevice, and general corrosion.

All our Super Duplex Steel UNS S32760 Flanges conform to international standards and are manufactured according to ASTM, ASME, DIN, ANSI, EN, WERKSTOFFE, JIS, BS standards. Each piece of Flanges is fully tested by professionals according to international standards. Also available at the best possible rates in the market.

Super Duplex Steel UNS S32760 Flanges Specification:

| A182 S32760 Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Super Duplex steel S32760 Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Super Duplex S32760 Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ASTM A182 S32760 Super Duplex Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASME SA 182 S32760 Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| ASME SA182 S32760 Super Duplex steel Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| A182 S32760 Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ASTM A182 S32760 Super Duplex Flange | Forged / Threaded / Screwed / Plate |

Super Duplex Steel UNS S32760 Flanges Chemical Composition:

Grade |

C | Si | Mn | Ni | P | S | Cr | Mo | W | N | Cu |

S32760 |

max 0.05 | max 1 | max 1 | 6 – 8 | max 0.030 | max 0.010 | 24 – 26 | 3 – 4 | 0.5 – 1 | 0.2 – 0.3 | 0.5 – 1 |

Mechanical Properties of Super Duplex Steel DIN 1.4410 Flanges:

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Super Duplex S32760 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 108778 , MPa – 750 | Psi – 80000 , MPa – 550 | 25 % |

Equivalent Grades of Super Duplex Steel UNS S32760 Flanges:

EUEN |

USA– |

FranceAFNOR |

GermanyDIN |

GB |

X2CrNiMoCuWN25-7-4( 1.4501) |

S32760 |

Z3CNDUW25-07Az |

1.4501 |

022Cr25Ni7Mo3WCuN |

Types of ASME SA182 Super Duplex Steel UNS S32760 Flanges material:

| ASTM A182 Super Duplex S32760 Slip on Flanges | • | Super Duplex Steel S32760 Pipe Flanges in Africa |

| UNS S32760 Super Duplex Blind Flanges | • | Super Duplex S32760 Orifice Flanges |

| Super Duplex S32760 Weld Neck Flanges Suppliers | • | Super Duplex S32760 RTJ Flanges Exporter in South America |

| S32760 Super Duplex Reducing Flanges | • | AISI Super Duplex DIN 1.4410 Socket weld Flanges |

| Super Duplex UNS S32760 Industrial Flanges | • | S32760 Super Duplex Plate Flanges in Europe |

| Super Duplex S32760 Loose Flanges | • | Super Duplex S32760 Forged Flanges |

| Super Duplex S32760 SORF Flanges | • | Super Duplex S32760 WNRF Flanges |

| Super Duplex S32760 Screwed Flanges | • | Super Duplex S32760 Ring Type Joint Flanges |

| Super Duplex UNS S32760 BLRF Flanges | • | S32760 Super Duplex Lap Joint Flanges |

Our Products

Our Blogs

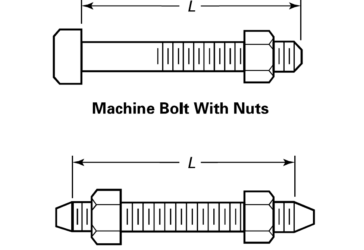

Flange Bolt Dimensions Chart and Stud Size in mm

I have discussed stud and bolt sizes used in plumbing in this article, along with a flange bolt dimension chart. The ASME B16.5 and B16.47 flange standards...

CITIES WE DELIVER

Rajkot, New Delhi, Chandigarh, Bogota, Bangkok, Secunderabad, Rio de Janeiro, Hanoi, Dallas, Courbevoie, Kuala Lumpur, Al Jubail, Dammam, Nagpur, Gurgaon, Sydney, Ankara, Karachi, London, Sharjah, Calgary, Visakhapatnam, Toronto, Vung Tau, Riyadh, Brisbane, Nashik, Milan, Port-of-Spain, Kolkata, Surat, Houston, Baroda, Cairo, Jamshedpur, New York, Ahmedabad, Al Khobar, Kuwait City, Kanpur, Los Angeles, Coimbatore, Vadodara, Thane, Ludhiana, Edmonton, Mumbai, Granada, Faridabad, Singapore, Montreal, Muscat, Abu Dhabi, Geoje-si, Ranchi, Chennai, Bengaluru, Madrid, Lahore, Thiruvananthapuram, Tehran, Ernakulam, Chiyoda, Seoul, Howrah, Algiers, Istanbul, Colombo, Atyrau, Doha, Gimhae-si, Jaipur, Indore, Manama, Navi Mumbai, Jakarta, Pimpri-Chinchwad, Hong Kong, Caracas, Ahvaz, Mexico City, Dubai, Lagos, Perth, Ulsan, Aberdeen, Melbourne, La Victoria, Pune, Noida, Jeddah, Petaling Jaya, Haryana, Santiago, Ho Chi Minh City, Bhopal, Hyderabad, Moscow, Busan, Kazakhstan, South Africa, Portugal, Italy, United States, Singapore, Costa Rica, Libya, Philippines, Afghanistan, Trinidad & Tobago,Tunisia, Finland, Sweden, China, New Zealand, Qatar, Iran, Denmark, Vietnam, Nigeria, Tibet, Peru, Malaysia, India, Jordan, Belarus, Iraq, Ireland, Thailand, Germany, Puerto Rico, Belgium, Mongolia, Greece, Kuwait, Pakistan, Zimbabwe, Ukraine, Canada, Azerbaijan, Romania, Ecuador, Hong Kong, Macau, Gambia, Norway, Namibia, Algeria, Australia, Oman, Bulgaria, Saudi Arabia, United Arab Emirates, France, Austria, Argentina, Mexico, Czech Republic, Iran, Russia, Nepal, Mexico, Yemen, Hungary, Serbia, Estonia, Turkey, Lebanon, Colombia, Slovakia, Taiwan, Kenya, Chile, Switzerland, Sri Lanka, Netherlands, United Kingdom, Egypt, Bahrain, Chile, Bhutan, Nigeria, Brazil, Bolivia, Bangladesh, Venezuela, Lithuania, Angola, Poland, Morocco, Japan, Gabon, Israel, Ghana, South Korea, Croatia, Poland, Spain, Indonesia.