ASTM A494 Nickel 201 Fasteners/ UNS N02201 Nickel Fasteners

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

N02201 Control Fasteners, Nickel 201 Ball Fastener, Nickel 200 Grub Screw, Premium Source Quality of ASTM A522 High Nickel Alloy 201 Ball Fastener, Forged Nickel Alloy 201 Fastener Suppliers in India, Nickel 200 Cup Point, Low-cost Range of ASTM A494 Nickel Alloy 201 Manifold Fasteners in Mumbai India, Grade 200 / 201 Nickel Check Fastener Exporters in India.

ASTM A494 Nickel Alloy 201 Instrument Connection Fasteners, Nickel 200 Cone Point, Nickel Alloy 201 Butterfly Fasteners, Nickel 201 Relief and Safety Fasteners Traders, UNS N02201 Nickel Gate Fasteners, Nickel 200 Dog Point, Nickel Alloy 201 Fixed Cone Fastener Dealers in India.

Detailed Information

Prashaant Steel & Alloys is well-known on the international market and is eager to include high-quality Nickel 201 Fasteners. Prashaant Steel & Alloys is a producer, supplier, stockiest, and exporter of Nickel 201 Fasteners, and exports the material to global customers at reasonable prices. Nickel 201 Fasteners are made in line with established manufacturing practises, allowing for the most effective use of raw materials. We market Nickel 201 Fasteners in custom thicknesses and styles to suit the needs of our customers. The bars are made under the close guidance of a knowledgeable team with considerable expertise in the industry. We also allow the use of modern equipment and cutting-edge technology, allowing Prashaant Steel & Alloys to achieve better results. Many quality standards for raw materials are also used to achieve production. The role of the quality control department in ensuring product quality is assuring in providing commendable product continuity. A number of raw material quality requirements are also taken into account during processing. The Quality Control Department’s role in ensuring product quality is to achieve reliable, commendable outcomes.

The fasteners exhibit superior resistance to reducing chemicals and caustic alkalis. These ensure good thermal conductivity, electrical and magnetostrictive properties. Furthermore, these exhibit some resistance to sulfuric and hydrochloric at modest temperature and concentrations.

In distilled and natural water these fasteners possess superior resistance. These are heat resistant and feature good toughness, durability, and hardenability in soaring temperatures. The fasteners are hot and cold formed through fabrication practices. The hot working is performed at temperature range 1200- 2250 degree F. After that the annealing is done at a temperature between 1300- 1600 degree F. meanwhile the welding of the fasteners is obtained by conventional welding methods.

The manufacturing of Nickel 201 Manifold Fasteners is done with the effective use of superior quality of raw materials with the latest technology and modern tools. The designing and fabrication of these Fasteners are done under the strict guidance of professional experts by considering raw material quality standards and manufacturing guidelines.

Few tests are mandatorily conducted for checking the product quality before shipping of the product. Tests like Positive Material Identification test, Intergranular Corrosion test, hardness test, pitting resistance test, chemical test, mechanical test, etc are conducted. Other tests are mechanical test, hardness test, compression test, leakage test, pressure test, micro test, macro test and more.

Grade 201 Nickel Alloy Fasteners Specification:

| Fasteners Material Specification | ASTM B 160 ASME SB 160, UNS 2201 Bolts |

|---|---|

| Standard | DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards |

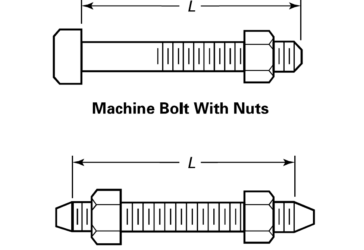

| Fasteners/ Bolts Size | M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160 |

| Length | 3 mm to 200 mm |

| Bolts, Studs Threads: | METRIC, BSW, BSF, UNC, UNF or as required |

| Fasteners Standard: |

ANSI – American National Standards Institute

DIN: DIN 931, DIN 933, DIN 934, DIN 970 UTS – Unified Thread Standard : UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization : ISO 4032, ISO 4033, JIS standards |

| SCOPE OF MANUFACTURE |

|

| Fasteners In Form of: | Hex, Square, Round, Threading as per Gauge Etc. |

Nickel Alloy ( N02201 / 2.4068) Fasteners Chemical Composition:

| Grade | C | Mn | Si | Cu | S | Mg | Ni | Ti | Fe |

| Ni Alloy 201 | 0.02 max | 0.35 max | 0.2 max | 0.25 max | 0.01 max | 0.15 max | 99.0 min | 0.1 max | 0.4 max |

201 Nickel ASME B16.5, B16.10, B16.25, B16.34 Fasteners Mechanical Properties:

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

ASTM A494M Nickel Alloy 201 Fasteners Equivalent Grades:

|

STANDARD |

UNS |

WERKSTOFF NR. |

AFNOR |

EN |

JIS |

BS |

GOST |

|

Nickel 201 |

N02201 |

2.4068 |

– |

LC-Ni 99 |

NW 2201 |

NA 12 |

НП-2 |

Prices of Nickel Alloy 201 Bolt & Nuts:

- Nickel 201 Bolt Bolts And High Strength Nickel Plated Carbon Steel Outer Hexagon Bolt

$0.01/ Piece - Bolts Alloy Bolt Prime Quality UNS N02201 2.4068 Nickel-based Alloy Hex Bolts And Nuts

$0.20/ Piece - 2.4068 alloy 201 UNS N02201 stainless nickel steel bolts and nuts

$1.00-$6.00/ Piece - Iso 4162/ Din 9621/En 1665 M7 M9 M6 UNS N02201 Hex Flange Bolt

$0.05-$2.00/ Piece

Types of Grade 201 Nickel Alloy Fasteners material:

- Ni Alloy 201 Stop Check Fasteners

- Nickel 201 Flange Fasteners

- Nickel 200 Dog Point

- Nickel Alloy 201 Strainers

- Nickel Alloy 201 Filters

- Nickel Alloy 201 HB-SERIES Needle Fastener

- Nickel 200 Cone Point

- Nickel Alloy 201 FB-SERIES Needle Fastener

- ASTM A522M Nickel Alloy 201 Swing Check Fastener Stockyards

- Nickel 200 Cup Point

- Nickel Alloy UNS N02201 Tilting Disc Check Fastener

- Nickel Alloy 201 B16.34 Double Block & Bleed Fasteners Traders

- Nickel Alloy 201 Relief and safety Fasteners stockyards

- Nickel 200 Grub Screw

- Largest Supplier of Nickel 201 Manual Fasteners

- Nickel Alloy 201 Lined Fasteners

Our Products

Our Blogs

Flange Bolt Dimensions Chart and Stud Size in mm

I have discussed stud and bolt sizes used in plumbing in this article, along with a flange bolt dimension chart. The ASME B16.5 and B16.47 flange standards...

CITIES WE DELIVER

Rajkot, New Delhi, Chandigarh, Bogota, Bangkok, Secunderabad, Rio de Janeiro, Hanoi, Dallas, Courbevoie, Kuala Lumpur, Al Jubail, Dammam, Nagpur, Gurgaon, Sydney, Ankara, Karachi, London, Sharjah, Calgary, Visakhapatnam, Toronto, Vung Tau, Riyadh, Brisbane, Nashik, Milan, Port-of-Spain, Kolkata, Surat, Houston, Baroda, Cairo, Jamshedpur, New York, Ahmedabad, Al Khobar, Kuwait City, Kanpur, Los Angeles, Coimbatore, Vadodara, Thane, Ludhiana, Edmonton, Mumbai, Granada, Faridabad, Singapore, Montreal, Muscat, Abu Dhabi, Geoje-si, Ranchi, Chennai, Bengaluru, Madrid, Lahore, Thiruvananthapuram, Tehran, Ernakulam, Chiyoda, Seoul, Howrah, Algiers, Istanbul, Colombo, Atyrau, Doha, Gimhae-si, Jaipur, Indore, Manama, Navi Mumbai, Jakarta, Pimpri-Chinchwad, Hong Kong, Caracas, Ahvaz, Mexico City, Dubai, Lagos, Perth, Ulsan, Aberdeen, Melbourne, La Victoria, Pune, Noida, Jeddah, Petaling Jaya, Haryana, Santiago, Ho Chi Minh City, Bhopal, Hyderabad, Moscow, Busan, Kazakhstan, South Africa, Portugal, Italy, United States, Singapore, Costa Rica, Libya, Philippines, Afghanistan, Trinidad & Tobago,Tunisia, Finland, Sweden, China, New Zealand, Qatar, Iran, Denmark, Vietnam, Nigeria, Tibet, Peru, Malaysia, India, Jordan, Belarus, Iraq, Ireland, Thailand, Germany, Puerto Rico, Belgium, Mongolia, Greece, Kuwait, Pakistan, Zimbabwe, Ukraine, Canada, Azerbaijan, Romania, Ecuador, Hong Kong, Macau, Gambia, Norway, Namibia, Algeria, Australia, Oman, Bulgaria, Saudi Arabia, United Arab Emirates, France, Austria, Argentina, Mexico, Czech Republic, Iran, Russia, Nepal, Mexico, Yemen, Hungary, Serbia, Estonia, Turkey, Lebanon, Colombia, Slovakia, Taiwan, Kenya, Chile, Switzerland, Sri Lanka, Netherlands, United Kingdom, Egypt, Bahrain, Chile, Bhutan, Nigeria, Brazil, Bolivia, Bangladesh, Venezuela, Lithuania, Angola, Poland, Morocco, Japan, Gabon, Israel, Ghana, South Korea, Croatia, Poland, Spain, Indonesia.