Stainless Steel Products

Stainless Steel 446 Forged Fittings/ UNS S44600 Forged Fittings

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

ASTM A182 Stainless Steel 446 Threaded Elbow, Stainless Steel 446 Threaded Forged Fittings, SS 446 Hex Plug, SS WERKSTOFF NR. 1.4401 Threaded Cross, SS 446 Threaded Plug, Stainless Steel 446 Hexagonal Plug, GOST 03Ch17N14M3 SS Full Couplings Exporter in India.

Stainless Steel 446 Threaded Fitting, SS 446 Threaded Fittings, SS 446 Threaded Pipe Elbow, 446 Stainless Steel Forged Threaded 90deg. Elbow, Stainless Steel 446 Threaded Cap, SS UNS S44600 Threaded Bushing, SS 446 Screwed Fittings Supplier in Mumbai, India.

Detailed Information

Prashaant Steel & Alloys is a popular producer and retailer of 446 Forged Fittings of Stainless Steel. In hostile conditions, ASME SA182 SS 446 Forged Fittings have a number of uses, such as Seawater. The ASTM A182 SS 446 Forged Fittings, made with a combination of chromium and molybdenum, give greater overall corrosion resistance than other forged stainless steel fittings, such as SS 304 and SS 304S Forged Fittings. The SS UNS S44600 Forged Fittings, with excellent welding properties, prevent carbide precipitation during the process of welding. Marine Grade stainless steel is generally known as ASTM A182 SS 446 Forged Fittings. At Prashaant Steel, we are respected for providing products that meet our customers’ quality standards, so our products undergo certain quality tests that only ensure good quality outputs. High Caliber Stainless Steel 446 Forged Fittings are manufactured and supplied by us at Prashaant Steel & Alloys. In a lot of industries, SS UNS S44600 Forged Fittings are found to have applications. Prashaant Steel & Alloys only outsources 446 Forged Fittings, which are equal to the specifications of the customer. We produce ASTM A182 SS 446 Forged Fittings that are reliable for use in a wide range of industries in a variety of sizes and dimensions. Custom size orders are also placed for ASTM A182 SS 446 Forged Fittings. At high temperatures, the SS UNS S44600 Forged Fittings we manufacture give greater creep, rupture stress and tensile strength. ASTM A182 SS 446 Forged Fittings have elevated durability due to their austenitic nature.

Around two to three percent of molybdenum is found in ASME SA182 SS 446 Forged Fittings, which allows the ASTM A182 SS 446 Forged Fittings to provide more tensile strength. During high temperatures, the SS UNS S44600 Forged Fittings also give elevated creep. The ASTM A182 SS 446 Forged Fittings are classified as Marine Grade Stainless steel because of their especially high corrosion resistance against chlorinated solutions and chlorides. Compared to the general 446 Forged Fittings, ASTM A182 SS 446 Forged Fittings have less carbon. Also at cryogenic temperatures, ASTM A182 SS 446 Forged Fittings still have greater oxidation characteristics. These SS UNS S44600 Forged Fittings give reduced precipitation at the grain boundary. This property helps to allow extensive use of ASTM A182 SS 446 Forged Fittings in heavy gauge welded components (over about about 6mm). The SS UNS S44600 Forged Fittings include the addition of nickel, manganese, and nitrogen to derive a microstructure. These forged fittings, being magnetic in nature, cannot be hardened by heat treatment. In heavy gauge welded sections, the ASTM A182 SS 446 Forged Fittings are used extensively. Forged fittings of 446 stainless steel deliver greater creep, rupture stress and tensile strength at elevated temperatures. In high-temperature cases, the SS UNS S44600 Forged Fittings perform very well. At ambient temperatures, the ASME SA182 SS 446 Forged Fittings are also corrosive to drinking water with up to around 1000 mg/L of chloride. We also manufacture ASTM A182 SS 446 Forged Fittings that have outstanding inter-granular corrosion resistance. ASTM A182 SS 446 Forged Fittings are commonly referred to as stainless steel of Marine Grade, but are not resistant to warm seawater. The SS UNS S44600 Forged Fittings show surface corrosion in many marine settings, as brown staining is typically noticeable. This staining is mostly due to crevices and rough surface finishing. In sporadic use, the ASME SA182 SS 446 Forged Fittings often give oxidation resistance of up to 870 °C and 925 °C in continuous use. Similar to the general ASTM A182 SS 446 Forged Fittings, the price of ASTM A182 SS 446 Forged Fittings is slightly more ductile and tough than that of ASTM A182 SS 446 Forged Fittings.

Prashaant Steel & Alloys also offers certain documentation with our products. Raw Material Test Reports, Packing List including net weight and gross weight, number of boxes, Marks and Numbers, Certificate of Origin legalized/attested by Chamber of Commerce or Embassy, Test Certificates certifying NACE MR0103, NACE MR0175, etc are some of the documents that we provide.

In multiple industries, applications of ASTM A182 SS 446 Forged Fittings are found. In the manufacture of marine parts, they are most prominently used. The SS UNS S44600 Forged Fittings are used to build boat fittings and chemical transportation containers. Some of the other countries that use ASTM A182 SS 446 Forged Fittings are laboratory bench and machinery, chemical and petrochemical equipment, brewery, dairy, and pharmaceutical production equipment, food processing equipment. For stamping, heading, and drawing, the ASTM A182 SS 446 Forged Fittings may also be used. In order to avoid weld decay, the ASTM A182 SS 446 forged fittings we manufacture can be annealed.

Stainless Steel 446 Forged Pipe Fittings Specification:

Specifications: ASTM A182 ASME SA182

Dimensions : ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799

Size: 1/8″ NB to 4″ NB

Type: Socket Weld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure: Threaded End – 2000 /3000/ 6000 LBS. Socket-weld End – 30006000/ 9000 LBS.

Chemical Composition of Stainless Steel 446 Forged Socket weld Fittings:

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 446 | 2.0 max | 1.5 max | 0.75 max | 0.040 max | 0.030 max | 23.00 – 30.00 | – | 0.50 max | 0.10 – 0.25 |

Mechanical Properties of SS 446 / S44600 / 1.4762 / SUS 446 High Pressure Forged Fittings:

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.5 g/cm3 | 1510 °C (2750 °F) | Psi – 75,000 , MPa – 485 | Psi – 40,000 , MPa – 275 | 20 % |

Stainless Steel 446 Equivalent Grades:

| Standard | SS 446 |

| UNS | S44600 |

| WERKSTOFF NR. | 1.4401 / 1.4436 |

| AFNOR | Z7CND17‐11‐02 |

| JIS | SUS 446 |

| GOST | – |

| BS | 446S31 / 446S33 |

| EN | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

Stainless Steel 446 Types:

| SS 446 Forged Fittings Manufacturer in India

Stainless Steel 446 Equal Cross SS 446 Reducing Cross Stockholder in India SS UNS S44600 Reducing Tee SS 446 Forged Welding Boss SS 446 Forged End Cap/Pipe Cap SS 446 Forged Reducers and Reducer Inserts Stainless Steel S44600 Forged Fittings in India SS 446 Forged Tee Stockist in Mumbai, India Stainless Steel 1.4762 Forged Plug 446 SS High Pressure Forged Fittings Stainless Steel 446 Industrial Forged Fittings SS 446 Socket weld Fittings Stainless Steel 446 Threaded Fittings |

SS 446 Socket weld Elbow

Stainless Steel 446 Forged Tee SS 446 Full Coupling Stainless Steel 446 Coupling Stainless Steel 446 90 deg. Threaded Elbow Stainless Steel 446 Half Coupling Stainless Steel 446 Union Stainless Steel 446 Forged Cross SS 446 Forged Pipe Nipple/Reducing Nipple Stainless Steel 446 Bushing SS 446 Threaded Unequal Tees Stainless Steel 1.4762 Forged Fittings in Mumbai SS 446 45 Degree Forged Elbow Stainless Steel 446 Forged Fittings Supplier in Mumbai |

Our Products

Our Blogs

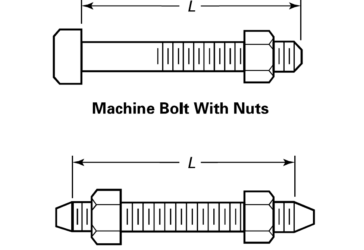

Flange Bolt Dimensions Chart and Stud Size in mm

I have discussed stud and bolt sizes used in plumbing in this article, along with a flange bolt dimension chart. The ASME B16.5 and B16.47 flange standards...