Alloy Steel Products

Alloy Steel ASTM A182 F11 Flanges

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

Stockist Of Alloy Steel F11 Flanges, Chrome Moly F11 Flanges, Alloy A182 F11 Weld Neck Flanges, Alloy Steel F11 Slip on Flanges, Alloy Steel F11 Pipe Flange, F11 Alloy Steel Blind Flanges Dealer, Alloy Steel F11 SWRF Flange Manufacturer in Mumbai, India.

ASTM A182 Chrome Moly F11 Threaded Flanges, Alloy Steel Gr. F11 Socket Weld Flanges, Alloy Steel F11 RTJ Flange, F11 Alloy Steel WNRF Flanges Exporter, Alloy Steel F11 Nippo Flanges, Chrome Moly F11 Blind Flanges, Alloy Steel F11 Weld Neck Flange Dealer in India.

Detailed Information

Prashaant Steel & Alloys is a major producer and supplier of the Alloy Steel F11 Flanges. The Alloy Steel F11 Flanges that we produce for applications inappropriate environments are crafted with absolute accuracy and dimensional quality. We at Prashaant Steel & Alloys are active in the manufacturing of Alloy Steel F11 Flanges superlative material, which has high resistivity against corrosion and oxidation under different conditions. Prashaant Steel & Alloys houses a production plant capable of processing Alloy Steel F11 Flanges bulk orders of different sizes and lengths. We also take custom orders from our customers and manufacture the Alloy Steel F11 Flanges according to their specifications and requirements. Because of their excellent formability properties, the Alloy Steel F11 Flanges that we produce are known to have diverse applications in various industrial sectors. We customers from all over the globe at Prashaant Steel & Alloys cater to both small and large industries. Thanks to the consistency of the Stainless Steel F11 Flanges we have we have established a reputation in the industry.

Alloy Steel F11 Flanges is done by soaking thoroughly at 1725 Degree F – 1850 Degree F (941 Degree C – 1010 Degree C), water quenched, which can only be hardened by cold work. As is true of other heat treating procedures, aging of Alloy Steel F11 Flanges is a time / temperature-dependent reaction, where the temperature is more important than time. Alloy Steel F11 Flanges was designed for mахіmum rеsіstаnсе tо асіd аttасk аnd dеmоnstrаtеs suреrіоr rеsіstаnсе tо strеss – соrrоsіоn сrасkіng іn bоіlіng 20 % tо 40 % sulphurіс асіd, аnd аlsо hаs ехсеllеnt gеnеrаl соrrоsіоn rеsіstаnсе tо sulfurіс асіd аnd tо сhlоrіdе strеss соrrоsіоn сrасkіng. Alloy Steel F11 Flanges hаs gооd mесhаnісаl рrореrtіеs аt bоth аmbіеnt аnd еlеvаtеd tеmреrаturеs, uр tо аррrохіmаtеlу 930 Degree F (500 Degree С) аnd іs rеаdіlу fаbrісаtеd bу usuаl іndustrіаl рrосеssеs. Because Alloy Steel F11 Flanges is essentially carbon–free, protective atmospheres are not required during annealing or aging. Alloy Steel F11 Flanges are also exceptionally stable during annealing and aging, offering predictable, uniform shrinkage on all dimensions. Alloy Steel F11 Flanges possess a higher resistance to precipitation of ferrite and sigma phases on cooling and welding than other stainless steels containing molybdenum.

The Alloy Steel F11 Flanges Applications are used in a broad variety of manufacturing industries. They are used for application in heat exchanger, condenser, and evaporator manufacturing industries. Pharmaceutical companies also utilize these. The F11 Round Alloy Steel Bars are also used in agricultural machinery and production equipment.

Specification of Alloy Steel F11 Flanges:

Specifications : ASTM A182 / ASME SA182

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2″ to 36″

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Chemical Composition of Alloy Steel F11 High Pressure Flanges:

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F11 | 0.15 max | 0.3-0.6 | 0.5 – 1 | 0.03 | 0.03 | 1 – 1.5 | 0.044 – 0.65 |

Mechanical Properties of Alloy Steel F11 A182 Flanges:

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| Alloy Steel F11 | 205 | 415 | 20 |

Equivalent Grades Alloy Steel F11 Flanges:

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

| Alloy Steel F11 | K11597 | 1.7338 | 1-1/4Cr-1/2Mo |

Types Of Grade F11 Alloy Steel Flanges

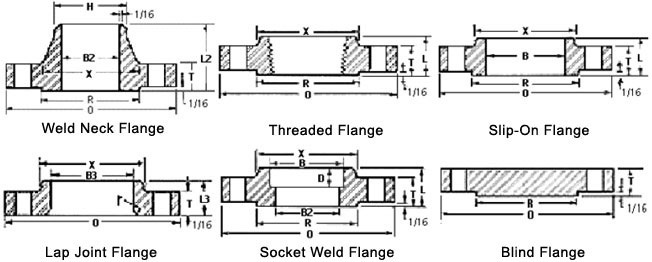

ASTM A182 Alloy Steel F11 Long Weld Neck Flanges

ASTM A182 Alloy Steel F11 Spectacle Blind Flanges

ASTM A182 Alloy Steel F11 Reducing Flanges

ASTM A182 Alloy Steel F11 Slip On Flanges

ASTM A182 Alloy Steel F11 Socket Weld Flanges

ASTM A182 Alloy Steel F11 Blind Flanges

ASTM A182 Alloy Steel F11 Weld Neck Flanges

ASTM A182 Alloy Steel F11 Threaded / Screwed Flanges

ASTM A182 Alloy Steel F11 Lap Joint Flanges

ASTM A182 Alloy Steel F11 Ring Type Joint Flanges

ASTM A182 Alloy Steel F11 Tongue & Groove Flanges

ASTM A182 Alloy Steel F11 Plate Flanges

ASTM A182 F11 Flanges Pressure Rating Table

| ASTM A182 F11 Flanges | Pressure And Temperature Ratings | ||||||

| Temperature °F | Class 150 As Per ASME B16.5 | Class 300 As Per ASME B16.5 | Class 400 As Per ASME B16.5 | Class 600 As Per ASME B16.5 | Class 900 As Per ASME B16.5 | Class 1500 As Per ASME B16.5 | Class 2500 As Per ASME B16.5 |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Alloy Steel F11 Flange Stud Bolt Size Chart

| 300# Flange As Per ANSI B16.5 | 600# Flange As Per ANSI B16.5 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Normal Pipe Size | # Studs And Bolts | Diameter of Studs And Bolts | Length Of Studs | # Studs And Bolts | Diameter of Studs And Bolts | Stud Length | # Studs And Bolts | Diameter of Studs And Bolts | Length Of Studs | |||

| 1/16 RF | RTJ | 1/16 RF | RTJ | 1/4 RF | RTJ | |||||||

| 1/2 | 4 | 0.50 | 2-1/4 | – | 4 | 0.50 | 2-1/2 | 3 | 4 | 0.50 | 3 | 3 |

| 3/4 | 4 | 0.50 | 2-1/2 | – | 4 | 0.63 | 3 | 3-1/2 | 4 | 0.63 | 3-1/2 | 3-1/2 |

| 1 | 4 | 0.50 | 2-1/2 | 3 | 4 | 0.63 | 3 | 3-1/2 | 4 | 0.63 | 3-1/2 | 3-1/2 |

| 1-1/4 | 4 | 0.50 | 2-3/4 | 3-1/4 | 4 | 0.63 | 3-1/4 | 3-3/4 | 4 | 0.63 | 3-3/4 | 3-3/4 |

| 1-1/2 | 4 | 0.50 | 2-3/4 | 3-1/4 | 4 | 0.75 | 3-1/2 | 4 | 4 | 0.75 | 4-1/4 | 4-1/4 |

| 2 | 4 | 0.63 | 3-1/4 | 3-3/4 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.63 | 4-1/4 | 4-1/4 |

| 2-1/2 | 4 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4 | 4-1/2 | 8 | 0.75 | 4-3/4 | 4-3/4 |

| 3 | 4 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/4 | 4-3/4 | 8 | 0.75 | 5 | 5 |

| 3-1/2 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/4 | 5 | 8 | 0.88 | 5-1/2 | 5-1/2 |

| 4 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/2 | 5 | 8 | 0.88 | 5-3/4 | 5-3/4 |

| 5 | 8 | 0.75 | 3-3/4 | 4-1/4 | 8 | 0.75 | 4-3/4 | 5-1/4 | 8 | 1.00 | 6-1/2 | 6-1/2 |

| 6 | 8 | 0.75 | 4 | 4-1/2 | 12 | 0.75 | 4-3/4 | 5-1/2 | 12 | 1.00 | 6-3/4 | 6-3/4 |

| 8 | 8 | 0.75 | 4-1/4 | 4-3/4 | 12 | 0.88 | 5-1/2 | 6 | 12 | 1.13 | 7-1/2 | 7-3/4 |

| 10 | 12 | 0.88 | 4-1/2 | 5 | 16 | 1.00 | 6-1/4 | 6-3/4 | 16 | 1.25 | 8-1/2 | 8-1/2 |

| 12 | 12 | 0.88 | 4-3/4 | 5-1/4 | 16 | 1.13 | 6-3/4 | 7-1/4 | 20 | 1.25 | 8-3/4 | 8-3/4 |

| 14 | 12 | 1.00 | 5-1/4 | 5-3/4 | 20 | 1.13 | 7 | 7-1/2 | 20 | 1.38 | 9-1/4 | 9-1/4 |

| 16 | 16 | 1.00 | 5-1/4 | 5-3/4 | 20 | 1.25 | 7-1/2 | 8 | 20 | 1.50 | 10 | 10 |

| 18 | 16 | 1.13 | 5-3/4 | 6-1/4 | 24 | 1.25 | 7-3/4 | 8-1/4 | 20 | 1.63 | 10-3/4 | 10-3/4 |

| 20 | 20 | 1.13 | 6-1/4 | 6-3/4 | 24 | 1.25 | 8 | 8-3/4 | 24 | 1.63 | 11-1/4 | 11-1/2 |

| 24 | 20 | 1.25 | 6-3/4 | 7-1/4 | 24 | 1.50 | 9 | 10 | 24 | 1.88 | 13 | 13-1/4 |

| 900# Flange As Per ANSI B16.5 | 1500# Flange As Per ANSI B16.5 | 2500# Flange As Per ANSI B16.5 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Normal Pipe Size | # Studs And Bolts | Diameter of Bolts And Studs | Stud Length | # Studs And Bolts | Diameter of Studs And Bolts | Length Of Studs | # Studs And Bolts | Diameter of Studs And Bolts | Length Of Studs | |||

| 1/4 RF | RTJ | 1/4 RF | RTJ | 1/4 RF | RTJ | |||||||

| 1/2 | 4 | 0.75 | 4-1/4 | 4-1/4 | 4 | 0.75 | 4-1/4 | 4-1/4 | 4 | 0.75 | 4-3/4 | 4-3/4 |

| 3/4 | 4 | 0.75 | 4-1/2 | 4-1/2 | 4 | 0.75 | 4-1/2 | 4-1/2 | 4 | 0.75 | 5 | 5 |

| 1 | 4 | 0.88 | 5 | 5 | 4 | 0.88 | 5 | 5 | 4 | 0.88 | 5-1/2 | 5-1/2 |

| 1-1/4 | 4 | 0.88 | 5 | 5 | 4 | 0.88 | 5 | 5 | 4 | 1.00 | 6 | 6 |

| 1-1/2 | 4 | 1.00 | 5-1/2 | 5-1/2 | 4 | 1.00 | 5-1/2 | 5-1/2 | 4 | 1.13 | 6-3/4 | 6-3/4 |

| 2 | 8 | 0.88 | 5-3/4 | 5-3/4 | 8 | 0.88 | 5-3/4 | 5-3/4 | 8 | 1.00 | 7 | 7 |

| 2-1/2 | 8 | 1.00 | 6-1/4 | 6-1/4 | 8 | 1.00 | 6-1/4 | 6-1/4 | 8 | 1.13 | 7-3/4 | 8 |

| 3 | 8 | 0.88 | 5-3/4 | 5-3/4 | 8 | 1.13 | 7 | 7 | 8 | 1.25 | 8-3/4 | 9 |

| 4 | 8 | 1.13 | 6-3/4 | 6-3/4 | 8 | 1.25 | 7-3/4 | 7-3/4 | 8 | 1.50 | 10 | 10-1/4 |

| 5 | 8 | 1.25 | 7-1/2 | 7-1/2 | 8 | 1.50 | 9-3/4 | 9-3/4 | 8 | 1.75 | 11-3/4 | 12-1/4 |

| 6 | 12 | 1.13 | 7-1/2 | 7-3/4 | 12 | 1.38 | 10-1/4 | 10-1/2 | 8 | 2.00 | 13-1/2 | 14 |

| 8 | 12 | 1.38 | 8-3/4 | 8-3/4 | 12 | 1.63 | 11-1/2 | 11-3/4 | 12 | 2.00 | 15 | 15-1/2 |

| 10 | 16 | 1.38 | 9-1/4 | 9-1/4 | 12 | 1.88 | 13-1/4 | 13-1/2 | 12 | 2.50 | 19-1/4 | 20 |

| 12 | 20 | 1.38 | 10 | 10 | 16 | 2.00 | 14-3/4 | 15-1/4 | 12 | 2.75 | 21-1/4 | 22 |

| 14 | 20 | 1.50 | 10-3/4 | 11 | 16 | 2.25 | 16 | 16-3/4 | – | – | – | – |

| 16 | 20 | 1.63 | 11-1/4 | 11-1/2 | 16 | 2.50 | 17-1/2 | 18-1/2 | – | – | – | – |

| 18 | 20 | 1.88 | 12-3/4 | 13-1/4 | 16 | 2.75 | 19-1/2 | 20-3/4 | – | – | – | – |

| 20 | 20 | 2.00 | 13-3/4 | 14-1/4 | 16 | 3.00 | 21-1/4 | 22-1/4 | – | – | – | – |

| 24 | 20 | 2.50 | 17-1/4 | 18 | 16 | 3.50 | 24-1/4 | 25-1/2 | – | – | – | – |

ASME SA182 GR F11 Weld Neck Flanges Gasket Chart

| Normal Pipe Size | Gasket I.D. (Inside Daimeter) | Gasket O.D. (Outside Daimeter) | ||||

|---|---|---|---|---|---|---|

| 150 LB | 300 LB | 400 LB | 600 LB | 900 LB | ||

| 1/2 | 0.84 | 1.875 | 2.125 | 2.125 | 2.125 | 2.50 |

| 3/4 | 1.06 | 2.25 | 2.625 | 2.625 | 2.625 | 2.75 |

| 1 | 1.31 | 2.625 | 2.875 | 2.875 | 2.875 | 3.125 |

| 1 1/4 | 1.66 | 3 | 3.25 | 3.25 | 3.25 | 3.50 |

| 1 1/2 | 1.91 | 3.375 | 3.75 | 3.75 | 3.75 | 3.875 |

| 2 | 2.38 | 4.125 | 4.375 | 4.375 | 4.375 | 5.625 |

| 2 1/2 | 2.88 | 4.875 | 5.125 | 5.125 | 5.125 | 6.50 |

| 3 | 3.50 | 5.375 | 5.875 | 5.875 | 5.875 | 6.625 |

| 4 | 4.50 | 6.875 | 7.125 | 7.00 | 7.625 | 8.125 |

| 5 | 5.56 | 7.75 | 8.50 | 8.375 | 9.50 | 9.75 |

| 6 | 6.62 | 8.75 | 9.875 | 9.75 | 10.50 | 11.375 |

| 8 | 8.62 | 11 | 12.125 | 12.00 | 12.625 | 14.125 |

| 10 | 10.75 | 13.375 | 14.25 | 14.125 | 15.75 | 17.125 |

| 12 | 12.75 | 16.125 | 16.625 | 16.50 | 18.00 | 19.625 |

SA182 F11 Cl2 Blind Flange Dimensional Tolerance

| ASTM A182 F11 Flanges | Tolerance Table | |

|---|---|---|

| A | O.D. (Outside Diameter) |

|

| D | Inside Diameter (I.D.) |

|

| B | Diameter of contact face |

|

| J | Diameter of hub at base |

|

| H | Diameter of hub at point of welding |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

|

|

| C | Thickness |

|

| K | Length of hub |

|

A182 F11 Socket Weld Flanges Dimensions Chart According to ASME B16.5

| Normal Pipe Size (NPS) | Outside Daimeter (O.D.) Of Flange | Thickness Of Flanges | Diameter of Raised Face | Hub at Base Diameter | Lengtd Tdru Hub | Bore And Diameter | Hub at Bevel Diameter | Radius of Fillet | Socket Deptd | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weld Neck (WN) | SORF (Slip-On) NPT (Threaded) SWRF (Socket) | Loose (Lap Joint) | SORF (Slip-on) SWRF (Socket) | Loose (Lap Joint) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

F11 Alloy Steel Spectacle Blind Flange Maximum Weight

| NPS (Nominal Pipe Size) | SORF (Slip On) | NPT (Threaded) | SWRF (Socket Weld) | Loose (Lap Joint) | BLRF (Blind) | WRNR (Weld Neck) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Size Chart Of A182 F11 Class 3 Long Weld Neck Flanges

| Normal Sizes In inch | Dimension | ASTM A182 F11 Flanges Dimensional Sizes 1/2 inch. to 2 1/2 inch. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 125 Class 150 |

Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 | ||||||||||

| inch. | mm | inch. | millimeter | inch. | mm | inch. | mm | inch. | mm | inch. | mm | inch | mm | |||

| 1/2 | A | 3 1/2 | 88.9 | 3 3/4 | 95.2 | 3 3/4 | 95.2 | 3 3/4 | 95.2 | 4 3/4 | 121 | 4 3/4 | 121 | 5 1/4 | 133.4 | |

| b | 7/16 | 11.1 | 9/16 | 14.3 | 9/16 | 14.3 | 9/16 | 14.3 | 7/8 | 22.2 | 7/8 | 22.2 | 1 3/16 | 30.2 | ||

| D2 | 1 3/8 | 34.9 | 1 3/8 | 34.9 | 1 3/8 | 34.9 | 1 3/8 | 34.9 | 1 3/8 | 34.9 | 1 3/8 | 34.9 | 1 3/8 | 34.9 | ||

| D1 | 2 3/8 | 60.3 | 2 5/8 | 66.7 | 2 5/8 | 66.7 | 2 5/8 | 66.7 | 3 1/4 | 82.6 | 3 1/4 | 82.6 | 3 1/2 | 88.9 | ||

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | – | 4 | 44 | ||

| d | 5/8 | 15.9 | 5/8 | 15.9 | 5/8 | 15.9 | 5/8 | 15.9 | 7/8 | 22.2 | 7/8 | 22.2 | 7/8 | 22.2 | ||

| 3/4 | A | 3 7/8 | 98.4 | 4 5/8 | 117.5 | 4 5/8 | 117.5 | 4 5/8 | 117.5 | 5 1/8 | 130 | 5 1/8 | 130 | 5 1/2 | 139.7 | |

| b | 1/2 | 12.7 | 5/8 | 15.9 | 5/8 | 15.9 | 5/8 | 15.9 | 1 | 25.4 | 1 | 25.4 | 1 1/4 | 31.8 | ||

| D2 | 1 11/16 | 42.9 | 1 11/16 | 42.9 | 1 11/16 | 42.9 | 1 11/16 | 42.9 | 1 11/16 | 42.9 | 1 11/16 | 42.9 | 1 11/16 | 42.9 | ||

| D1 | 2 3/4 | 69.8 | 3 1/4 | 82.5 | 3 1/4 | 82.5 | 3 1/4 | 82.5 | 3 1/2 | 88.9 | 3 1/2 | 88.9 | 3 3/4 | 95.2 | ||

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | – | 4 | 44 | ||

| d | 5/8 | 15.9 | 3/4 | 19 | 3/4 | 19 | 3/4 | 19 | 7/8 | 22.2 | 7/8 | 22.2 | 7/8 | 22.2 | ||

| 1 | A | 4 1/4 | 108 | 4 7/8 | 123.8 | 4 7/8 | 123.8 | 4 7/8 | 123.8 | 5 7/8 | 149.2 | 5 7/8 | 149.2 | 6 1/4 | 159 | |

| b | 9/16 | 14.3 | 11/16 | 17.5 | 11/16 | 17.5 | 11/16 | 17.5 | 1 1/8 | 28.6 | 1 1/8 | 28.6 | 1 3/8 | 34.9 | ||

| D2 | 2 | 50.8 | 2 | 50.8 | 2 | 50.8 | 2 | 50.8 | 2 | 50.8 | 2 | 50.8 | 2 | 50.8 | ||

| D1 | 3 1/8 | 79.4 | 3 1/2 | 88.9 | 3 1/2 | 88.9 | 3 1/2 | 88.9 | 4 | 102 | 4 | 102 | 4 1/4 | 108 | ||

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| d | 5/8 | 15.9 | 3/4 | 19 | 3/4 | 19 | 3/4 | 19 | 1 | 25.4 | 1 | 25.4 | 1 | 25.4 | ||

| 1 1/4 | A | 4 5/8 | 117.5 | 5 1/4 | 133.4 | 5 1/4 | 133.4 | 5 1/4 | 133.4 | 6 1/4 | 159 | 6 1/4 | 159 | 7 1/4 | 184.2 | |

| b | 5/8 | 15.9 | 3/4 | 19 | 13/16 | 20.6 | 13/16 | 20.6 | 1 1/8 | 28.6 | 1 1/8 | 28.6 | 1 1/2 | 38.1 | ||

| D2 | 2 1/2 | 63.5 | 2 1/2 | 63.5 | 2 1/2 | 63.5 | 2 1/2 | 63.5 | 2 1/2 | 63.5 | 2 1/2 | 63.5 | 2 1/2 | 63.5 | ||

| D1 | 3 1/2 | 88.9 | 3 7/8 | 98.4 | 3 7/8 | 98.4 | 3 7/8 | 98.4 | 4 3/8 | 111 | 4 3/8 | 111 | 5 1/8 | 130 | ||

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| d | 5/8 | 15.9 | 3/4 | 19 | 3/4 | 19 | 3/4 | 19 | 1 | 25.4 | 1 | 25.4 | 1 1/8 | 28.6 | ||

| 1 1/2 | A | 5 | 127 | 6 1/8 | 155.6 | 6 1/8 | 155.6 | 6 1/8 | 155.6 | 7 | 177.8 | 7 | 177.8 | 8 | 203 | |

| b | 11/16 | 17.5 | 13/16 | 20.6 | 7/8 | 22.2 | 7/8 | 22.2 | 1 1/4 | 31.8 | 1 1/4 | 31.8 | 1 3/4 | 44.5 | ||

| D2 | 2 7/8 | 73 98 | 2 7/8 | 73 | 2 7/8 | 73 | 2 7/8 | 73 | 2 7/8 | 73 | 2 7/8 | 73 | 2 7/8 | 73 | ||

| D1 | 3 7/8 | 4 | 4 1/2 | 114 | 4 1/2 | 114 | 4 1/2 | 114 | 4 7/8 | 124 | 4 7/8 | 124 | 5 3/4 | 146 | ||

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| d | 5/8 | . 15.9 | 7/8 | 22.2 | 7/8 | 22.2 | 7/8 | 22.2 | 1 1/8 | 28.6 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | ||

| 2 | A | 6 | 152.4 | 6 1/2 | 165.1 | 6 1/2 | 165.1 | 6 1/2 | 165.1 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 9 1/4 | 234.9 | |

| b | 3/4 | 19 | 7/8 | 22.2 | 1 | 25.4 | 1 | 25.4 | 1 1/2 | 38.1 | 1 1/2 | 38.1 | 2 | 50.8 | ||

| D2 | 3 5/8 | 92.1 | 3 5/8 | 92.1 | 3 5/8 | 92.1 | 3 5/8 | 92.1 | 3 5/8 | 92.1 | 3 5/8 | 92.1 | 3 5/8 | 92.1 | ||

| D1 | 4 3/4 | 121 | 5 | 127 | 5 | 127 | 5 | 127 | 6 1/2 | 165.1 | 6 1/2 | 165.1 | 6 3/4 | 171 | ||

| n | 4 | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 3/4 | 19 | 3/4 | 19 | 3/4 | 19 | 3/4 | 19 | 1 | 25.4 | 1 | 25.4 | 1 1/8 | 28.6 | ||

| 2 1/2 | A | 7 | 177.8 | 7 1/2 | 190.5 | 7 1/2 | 190.5 | 7 1/2 | 190.5 | 9 5/8 | 244 | 9 5/8 | 244 | 10 1/2 | 266.7 | |

| b | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/8 | 28.6 | 1 5/8 | 41.3 | 1 5/8 | 41.3 | 2 1/4 | 57.2 | ||

| D2 | 4 1/8 | 104.8 | 4 1/8 | 104.8 | 4 1/8 | 104.8 | 4 1/8 | 104.8 | 4 1/8 | 105 | 4 1/8 | 105 | 4 1/8 | 105 | ||

| D1 | 5 1/2 | 139.7 | 5 7/8 | 149.2 | 5 7/8 | 149.2 | 5 7/8 | 149.2 | 7 1/2 | 190.5 | 7 1/2 | 190.5 | 7 3/4 | 197 | ||

| n | 4 | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 7/8 | 22.2 | 7/8 | 22.2 | 1 1/8 | 28.6 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | ||

Grade F11 Class 1 Slip On Flanges Thickness Chart MM

| Wall Thickness Of ASTM A182 F11 Flanges | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Normal Pipe Size (NPS) | O.D. (Outside Daimeter) | Sch 10 | Sch 20 | Sch 30 | STD Wall Outside Daimeter | Sch 40 | Sch 60 | EXT Hvy Outside Daimeter | Schedule 80 | Schedule 100 | Schedule 120 | Schedule 140 | Schedule 160 | XX Hvy |

| ½ | 0.84 | 0.083 | … | … | 0.109 | 0.109 | … | 0.147 | 0.147 | … | … | … | 0.188 | 0.294 |

| ¾ | 1.05 | 0.083 | … | … | 0.113 | 0.113 | … | 0.154 | 0.154 | … | … | … | 0.219 | 0.308 |

| 1 | 1.315 | 0.109 | … | … | 0.133 | 0.133 | … | 0.179 | 0.179 | … | … | … | 0.25 | 0.358 |

| 1 ¼ | 1.66 | 0.109 | … | … | 0.14 | 0.14 | … | 0.191 | 0.191 | … | … | … | 0.25 | 0.382 |

| 1 ½ | 1.9 | 0.109 | … | … | 0.145 | 0.145 | … | 0.2 | 0.2 | … | … | … | 0.281 | 0.4 |

| 2 | 2.375 | 0.109 | … | … | 0.154 | 0.154 | … | 0.218 | 0.218 | … | … | … | 0.344 | 0.436 |

| 2 ½ | 2.875 | 0.12 | … | … | 0.203 | 0.203 | … | 0.276 | 0.276 | … | … | … | 0.375 | 0.552 |

| 3 | 3.5 | 0.12 | … | … | 0.216 | 0.216 | … | 0.3 | 0.3 | … | … | … | 0.438 | 0.6 |

| 3 ½ | 4 | 0.12 | … | … | 0.226 | 0.226 | … | 0.318 | 0.318 | … | … | … | … | 0.636 |

| 4 | 4.5 | 0.12 | … | … | 0.237 | 0.237 | … | 0.337 | 0.337 | … | 0.438 | … | 0.531 | 0.674 |

| 5 | 5.563 | 0.134 | … | … | 0.258 | 0.258 | … | 0.375 | 0.375 | … | 0.5 | … | 0.625 | 0.75 |

| 6 | 6.625 | 0.134 | … | … | 0.28 | 0.28 | … | 0.432 | 0.432 | … | 0.562 | … | 0.719 | 0.864 |

| 8 | 8.625 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 |

| 10 | 10.75 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 |

| 12 | 12.75 | 0.18 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 |

| 14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | … |

| 16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | … |

| 18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | … |

| 20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | … |

| 22 | 22 | 0.25 | … | … | 0.375 | … | … | 0.5 | … | … | …. | …. | …. | …. |

| 24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | …. |

| 26 | 26 | …. | …. | …. | 0.375 | …. | …. | 0.5 | …. | …. | …. | …. | …. | …. |

| 30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | …. | …. | 0.5 | …. | …. | …. | …. | …. | …. |

| 36 | 36 | 0.312 | 0.5 | 0.625 | 0.375 | 0.75 | …. | 0.5 | …. | …. | …. | …. | …. | …. |

| 40 | 40 | …. | …. | …. | 0.375 | …. | …. | 0.5 | …. | …. | …. | …. | …. | …. |

| 42 | 42 | …….. | …….. | …….. | 0.375 | …….. | …….. | 0.5 | …….. | …….. | …….. | …….. | …….. | …….. |

| 48 | 48 | …….. | …….. | …….. | 0.375 | …….. | …….. | 0.5 | …….. | …….. | …….. | …….. | …….. | …….. |

Types Of Alloy Steel ASTM A182 F11 Flanges :

| F11 Alloy Steel Blind Flange | Chromium Molybdenum F11 Flat Flange Supplier in India |

| Cr-Mo UNS K11597 Flanges Manufacturer | Alloy Steel F11 Slip on Flanges |

| Cr-Mo F11 Weld Neck Flanges | Chromium Molybdenum Steel F11 Socket weld Flanges Dealer in India |

| Alloy Steel A182 F11 Long Weld Neck Flanges Stockist | ASTM A182 F11 Alloy Steel Threaded Flanges |

| Cr-Mo F11 Flanges Supplier in India | Alloy Steel EN 1092-1 Plate Flanges |

| CrMo F11 Forged Flanges Wholesaler | Chrome Moly UNS K11597 Lap Joint Flanges Supplier |

| Alloy Steel F11 BLRF Flange Manufacturer | Cr-Mo F11 Raised Face Flanges |

| F11 Alloy Steel Nipoflange | Cr-Mo Alloy Steel F11 Reducing Flanges |

| ANSI B16.5 Alloy Steel F11 Pipe Flange | Chromium Molybdenum Steel A182 F11 Ring Type Joint Flanges |

| 1.7338 Cr-Mo Orifice Flange | Alloy Steel F11 Spectacle Blind Flanges Stockists |

| Cr-Mo F11 PN 10 Flange | F11 PN 16 Alloy Steel Flanges Stockists |

| Cr-Mo F11 DIN Flanges | Alloy Steel 1.7338 Alloy Steel SORF Flanges Exporter |

| ASME B16.5 Alloy Steel F11 Flanges | ASTM A182 F11 Tongue & Groove Flanges |

| Alloy Steel F11 Male & Female Flanges | CrMo F11 RTJF Flanges |

Our Products

CITIES WE DELIVER

Rajkot, New Delhi, Chandigarh, Bogota, Bangkok, Secunderabad, Rio de Janeiro, Hanoi, Dallas, Courbevoie, Kuala Lumpur, Al Jubail, Dammam, Nagpur, Gurgaon, Sydney, Ankara, Karachi, London, Sharjah, Calgary, Visakhapatnam, Toronto, Vung Tau, Riyadh, Brisbane, Nashik, Milan, Port-of-Spain, Kolkata, Surat, Houston, Baroda, Cairo, Jamshedpur, New York, Ahmedabad, Al Khobar, Kuwait City, Kanpur, Los Angeles, Coimbatore, Vadodara, Thane, Ludhiana, Edmonton, Mumbai, Granada, Faridabad, Singapore, Montreal, Muscat, Abu Dhabi, Geoje-si, Ranchi, Chennai, Bengaluru, Madrid, Lahore, Thiruvananthapuram, Tehran, Ernakulam, Chiyoda, Seoul, Howrah, Algiers, Istanbul, Colombo, Atyrau, Doha, Gimhae-si, Jaipur, Indore, Manama, Navi Mumbai, Jakarta, Pimpri-Chinchwad, Hong Kong, Caracas, Ahvaz, Mexico City, Dubai, Lagos, Perth, Ulsan, Aberdeen, Melbourne, La Victoria, Pune, Noida, Jeddah, Petaling Jaya, Haryana, Santiago, Ho Chi Minh City, Bhopal, Hyderabad, Moscow, Busan, Kazakhstan, South Africa, Portugal, Italy, United States, Singapore, Costa Rica, Libya, Philippines, Afghanistan, Trinidad & Tobago,Tunisia, Finland, Sweden, China, New Zealand, Qatar, Iran, Denmark, Vietnam, Nigeria, Tibet, Peru, Malaysia, India, Jordan, Belarus, Iraq, Ireland, Thailand, Germany, Puerto Rico, Belgium, Mongolia, Greece, Kuwait, Pakistan, Zimbabwe, Ukraine, Canada, Azerbaijan, Romania, Ecuador, Hong Kong, Macau, Gambia, Norway, Namibia, Algeria, Australia, Oman, Bulgaria, Saudi Arabia, United Arab Emirates, France, Austria, Argentina, Mexico, Czech Republic, Iran, Russia, Nepal, Mexico, Yemen, Hungary, Serbia, Estonia, Turkey, Lebanon, Colombia, Slovakia, Taiwan, Kenya, Chile, Switzerland, Sri Lanka, Netherlands, United Kingdom, Egypt, Bahrain, Chile, Bhutan, Nigeria, Brazil, Bolivia, Bangladesh, Venezuela, Lithuania, Angola, Poland, Morocco, Japan, Gabon, Israel, Ghana, South Korea, Croatia, Poland, Spain, Indonesia.

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad and Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.