Alloy Steel Products

What is Alloy Steel?

Alloy steel is created by combining carbon steel with additional components made up of metals and non-metals. The environmental, chemical, and physical characteristics of these alloy steels might change depending on the alloying constituents. In this case, the ratio of alloying components can offer various mechanical qualities.

Our Products

There are multiple subcategories of alloy steel. These include:

- High-strength low alloy (HSLA) steel

- High-alloy steel

- Stainless steel

- Microalloyed steel

- Advanced high-strength steel (AHSS)

- Maraging steel

- Tool steel

Alloying elements

There are around 20 alloying elements that can be added to carbon steel to produce various grades of alloy steel. These provide different types of properties. Some of the elements used and their effects include:

- Aluminium – can rid steel of phosphorous, sulfur and oxygen

- Chromium – can increase toughness, hardness and wear resistance

- Copper – can increase corrosion resistance and harness

- Manganese – can increase high-temperature strength, wear resistance, ductility and hardenability

- Nickel – can increase corrosion, oxidation resistance and strength

- Silicon – can increase magnetism and strength

- Tungsten – can increase strength and hardness

- Vanadium – can increase corrosion, shock resistance, strength and toughness

Properties of Alloy Steel

Alloy steels can contain a wide range of elements, and each one can improve the material’s ability to resist corrosion, heat, and mechanical stress. While higher additions of up to 20 wt.% boost corrosion resistance and stability at high or low temperatures, smaller additions of less than 5 wt.% tend to improve mechanical qualities, such as improving hardenability and strength.

The table below summarises the effects of adding various elements to steel along with typical weight fractions.

|

Element |

Symbol |

wt. % |

Function |

|

Aluminium |

Al |

0.95–1.30 |

Alloying element in nitriding steels |

|

Bismuth |

Bi |

– |

Improves machinability |

|

Boron |

B |

0.001–0.003 |

Improves hardenability |

|

Chromium |

Cr |

0.5–2.0 |

Improves hardenability |

|

4–18 |

Corrosion resistance |

||

|

Copper |

Cu |

0.1–0.4 |

Corrosion resistance |

|

Lead |

Pb |

– |

Improves machinability |

|

Manganese |

Mn |

0.25–0.40 |

Prevents brittleness in combination with sulfur |

|

>1 |

Increases hardenability |

||

|

Molybdenum |

Mo |

0.2–0.5 |

Inhibits grain growth |

|

Nickel |

Ni |

2–5 12–20 |

Increases toughness Improves corrosion resistance |

|

Silicon |

Si |

0.2–0.7 |

Increases strength and hardenability |

|

2 |

Increases yield strength (spring steel) |

||

|

Higher % |

Increases magnetic properties |

||

|

Sulfur |

S |

0.08–0.15 |

Improves machinability (free-machining steel properties) |

|

Titanium |

Ti |

– |

Reduces martensitic hardness in Cr steels |

|

Tungsten |

W |

– |

Increases hardness at high temperatures |

|

Vanadium |

V |

0.15 |

Increases strength while maintaining ductility, promotes fine grain structure |

Alloy Steel Products and Their Applications,

Numerous goods can be produced using alloy steels of different compositions. These include alloy steel fasteners, alloy steel flanges, alloy steel plates, sheets, and coils, alloy steel bars, rods, and wires, as well as alloy steel forged fittings and alloy steel buttweld fittings. Automobiles, mining, machinery, railroads, road construction, buildings, appliances, and off-shore applications are just a few of the industries that use alloy steel.

- Applications in building large structures

Alloy steels are utilised in the building and construction sector to create the steel skeleton of very big modern constructions including stadiums, skyscrapers, bridges, airports, and bridges. Steel alloys have the necessary high strength to maintain such massive buildings. Alloy steels are used as reinforcement in concrete structures to increase strength and decrease overall structural weight. The building and construction industry uses smaller objects made of alloy steels like screws, nails, and bolts.

- Applications in Building Bridges

Weathering steels, a specific alloy steel, are used in bridge construction. Because these have nickel, copper, and chromium as alloying components, they offer improved corrosion protection. Weathering steels are frequently used in structures as a decorative face material. High safety, ease and speed of construction, aesthetically pleasing appearance, shallow depth of construction, low maintenance, and adaptability to future changes are only a few advantages of weathering steel. Considering its.

- Alloy Steel Flat Products

Flat items like plates and strips are produced using alloy steels. There are many different sizes and grades of plates. These are welded into prefabricated parts during building construction from plates.

- Alloy Steel Strip and Coil Products

Hot-dipped galvanised coils and cold-rolled strips are both options for strips. Construction goods like wall and roof cladding, side rails, roof purlins, light steel frames, and lintels are made from hot-dipped galvanised coils.

- Alloy Steel Long Products

Alloy steels are employed in producing long products used in the construction industry such as girders, structural sections, bars, rails, rods and wires.

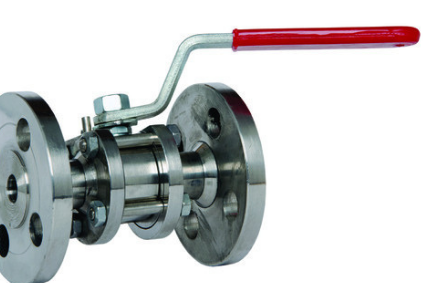

- Alloy Steel Flanges

Flanges are yet another significant alloy steel product. Pipelines made of stainless steel employ these. These flanges can be customised to fit a range of uses. Some of them have weld neck flanges, which can function effectively in extreme situations like high pressure, high temperature, or subzero temperatures and have the same thickness and bevel as the pipe. Slip-on flanges for alloy steel pipelines that need routine maintenance and inspection are lap joint flanges.

- Alloy Steel Pipe Products

Due to their performance qualities, such as ductility, ease of fastening without heat treatment, and high durability, alloy steel pipes are crucial building and construction materials. They are an alloy of nickel, chromium, and stainless steel. Large diameter welded pipes, electric fusion welded pipes, welded pipes, and seamless pipes are a few unique varieties of alloy steel pipes. In addition to high-pressure applications, they are also very beneficial for high-temperature or corrosive environments.

Our Products

Get In Touch

Contact Person

Call Us at

Feel free to call on +91 91674 18473

Drop Mail On

For Domestic Queries: [email protected], [email protected]

For International Queries: [email protected]

Find Us at

Gulalwadi, Mumbai – 400004, Maharashtra, India

Contact Our Sales Team

Our team is happy to answer your sales question. Fill out the form and we’ll be in touch as soon as possible.