Incoloy Products

Incoloy 825 Forged Fittings

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

Incoloy 825 Threaded Pipe Elbow, Inconel 825 Hexagonal Plug, Incoloy UNS N08825 Threaded Coupling Exporter, 825 Alloy Threaded Forged 90deg. Elbow, Incoloy 825 Threaded Cross, Alloy DIN NR. 2.4858 Screwed Fittings Exporter in India.

Incoloy 825 Threaded Forged Fittings, Incoloy 825 Threaded Tee, ASTM B564 Incoloy 825 Threaded Elbow, Inconel 825 Lateral Tee, 825 Incoloy Threaded Cap Manufacturer and Suppliers In Mumbai, India, Incoloy 825 Forged Fittings Price in India

Detailed Information

Prashaant Steel & Alloys is one of the top leading ASTM B366 Incoloy 825 Forged Fittings producers and suppliers of quite a high standard. At Prashaant Steel & Alloys, we are interested in providing a broad variety of ASTM B366 Incoloy Forged Fittings, which differ in various requirements. We provide the customers with these ASTM B366 Incoloy Forged Fittings in numerous types, weights, thickness, height, etc. Such Forged Fittings are shipped internationally to the consumers at fair prices as well as at reduced rates. The usage of the highest standard of Raw materials is essential in the production sector. Incoloy’s high-grade alloy is used in the manufacturing of Incoloy 825 Forged Fittings so that the Forged Fittings can be quickly attached to greater power. The effective usage of the new equipment accessible and the latest devices that we house at Prashaant Steel & Alloys render the commodity of superior quality.

We at Prashaant Steel & Alloys are known to be 825 Forged Fittings of First-rate standard of manufacturing and supplying. The 825 Forged Fittings we produce are made sure to fulfill our clients ‘ needs and demands. The Incoloy 825 Forged Fittings which we provide high resistance to corrosion and oxidation. The Incoloy 825 Forged Fittings also provide high degree of formability and weldability. The 825 Forged Fittings are ideal for usage in several different industries. We conduct several quality tests to ensure the quality of our products and dismiss all of the default products. In order to insure that the commodity is delivered as expected, Prashaant Steel & Alloys suppliers the wrapped goods to the 825 Forged Fittings packaged in suitable wooden boxes guaranteeing that the commodity is minimally degraded.

ASTM B366 Incoloy Forged Fittings are produced from alloy based on chromium, nickel, iron alongside copper and molybdenum. They contain huge quantities of Nickel, which helps them to resist Chloride ion stress cracking. The ASME SB564 Incoloy Forged Fittings are highly corrosion resisting Forged Fittings. They also contain Chromium, which boosts their resistivity against oxidizing conditions such as oxidizing salts and nitric acid solutions. The molybdenum and copper amounts require the 825 Forged Fittings to withstand reducing agents and acids. The Stable austenite structures of these Incoloy Forged Fittings make them suitable to function at very high temperatures. Incoloy 825 Circular Forged Fittings are therefore completely pitting, abrasion, and corrosion prone. Additionally, it is completely phosphoric and sulfuric acid resistant. In addition, the ASTM B366 Incoloy Forged Fittings have improved potential to provide strong tensile strength, stability, longevity and long-lasting capacity. The ASTM B366 Incoloy Forged Fittings have reasonable dimensional precision, are robustly built, have outstanding surface finishes, are able to withstand heavy loads and sustain high temperatures. They also resist pitting and inter-granular attack after fabrication. The 825 Forged Fittings are stabilized with titanium to resist pitting and inter-granular attack after fabrication, particularly welding, which requires heating in the critical temperature range of sensitization (650 ° C-760 ° C). 825 Forged Fittings have excellent corrosion protection from sulfuric and phosphoric acids and are also the most cost-effective 825 Forged Fittings in the sulfuric acid operation. 825 Forged Fittings exhibit strong mechanical properties from cryogenic to relatively hot temperatures. Exposure to temperatures above around 1000 ° F (540 ° C) may result in microstructural changes (phase formation) that significantly lower ductility and resistance to effect.

These ASME SB564 Incoloy Forged Fittings are found in application in numerous industrial sectors. Acid production piping, Chemical process equipment, and Marine exhaust systems are some common applications of these Forged Fittings. They are also used in industries for Sulfuric acid piping and vessels, seawater piping systems and sour gas oil wells. Phosphoric acid evaporators are also manufactured using the ASME SB564 Incoloy Forged Fittings. ASTM B366 Incoloy Forged Fittings applications can be used in different sectors such as chlorination systems manufacturing and acid processing and pickling systems. The ASTM B366 Incoloy Forged Fittings are also used in power plants and pulp and paper bleach plants for outlet ducting and rack liner applications. Such ASTM B366 Incoloy Forged Fittings are used for chemical manufacturing, emission management devices, well piping of oil and gas, reprocessing of nuclear waste, generating acids, and pickling devices. The 825 Forged Fittings are also used in their implementations by the Pulp and Paper industries. You will consider some of the other 825 round bar products in Off-Shore Oil Exploration Firms. They are also used in industries such as Petroleum and Chemical Industries.

Incoloy 825 Forged Fittings Specification:

Size: 1/8” NB to 4” NB (Socket weld & Screwed-Threaded)

Specification: ASTM B564 & ASME SB564

Standard: ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Class: 2000 LBS, 3000 LBS, 6250 LBS, 9000 LBS

Type: Socket weld Fittings, Screwed-Threaded Fittings

Incoloy 825 Forged Socketweld Fittings Chemical Composition:

| Element | C | Mn | Si | Cu | Al | S | Fe | Ni |

| Monel K500 | 0.25 max | 1.5 max | 0.5 max | 27.0 – 33.0 | 2.3 – 3.15 | 0.010 max | 05 – 2 | 63.0 min |

Incoloy 825 Forged Threaded Fittings Mechanical & Physical Properties:

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

INCOLOY 825 FORGED FITTINGS EQUIVALENT GRADES

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo |

TYPES OF INCOLOY 825 FORGED FITTINGS

- B564 UNS N08825 Incoloy 825 Socket Weld Fittings

- B564 UNS N08825 Incoloy 825 90 Deg Socket Weld Elbow

- B564 UNS N08825 Incoloy 825 45 Deg Socket Weld Elbow

- B564 UNS N08825 Incoloy 825 Socket Weld Equal Tee

- B564 UNS N08825 Incoloy 825 Socket Weld Unequal Tee

- B564 UNS N08825 Incoloy 825 Socket Weld Equal Cross

- B564 UNS N08825 Incoloy 825 Socket Weld Unequal Cross

- B564 UNS N08825 Incoloy 825 Socket Weld Full Coupling

- B564 UNS N08825 Incoloy 825 Socket Weld Half Coupling

- B564 UNS N08825 Incoloy 825 Socket Weld Pipe Cap

- B564 UNS N08825 Incoloy 825 Socket Weld Union

- B564 UNS N08825 Incoloy 825 Socket Weld Reducer Insert

- B564 UNS N08825 Incoloy 825 Socket Weld Boss

- B564 UNS N08825 Incoloy 825 90 Deg Socket Weld Elbow Outlet

- B564 UNS N08825 Incoloy 825 Socket Weld Boss

- B564 UNS N08825 Incoloy 825 Socket Weld Lateral Outlet

- B564 UNS N08825 Incoloy 825 Branch Outlet

- B564 UNS N08825 Incoloy 825 90 Deg Elbow Outlet

- B564 UNS N08825 Incoloy 825 Lateral Outlet

- B564 UNS N08825 Incoloy 825 Nipple Branch Outlet

- B564 UNS N08825 Incoloy 825 Socket Weld Fittings

- B564 UNS N08825 Incoloy 825 Socket Weld Pipe Nipples

- B564 UNS N08825 Incoloy 825 Socket Weld Pipe Outlet Fittings

- B564 UNS N08825 Incoloy 825 Socket Weld Swage Nipples | Pipe Swage

- B564 UNS N08825 Incoloy 825 Socket Weld Branch Outlet

Our Products

Our Blogs

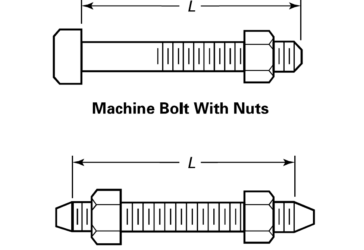

Flange Bolt Dimensions Chart and Stud Size in mm

I have discussed stud and bolt sizes used in plumbing in this article, along with a flange bolt dimension chart. The ASME B16.5 and B16.47 flange standards...

CITIES WE DELIVER

Rajkot, New Delhi, Chandigarh, Bogota, Bangkok, Secunderabad, Rio de Janeiro, Hanoi, Dallas, Courbevoie, Kuala Lumpur, Al Jubail, Dammam, Nagpur, Gurgaon, Sydney, Ankara, Karachi, London, Sharjah, Calgary, Visakhapatnam, Toronto, Vung Tau, Riyadh, Brisbane, Nashik, Milan, Port-of-Spain, Kolkata, Surat, Houston, Baroda, Cairo, Jamshedpur, New York, Ahmedabad, Al Khobar, Kuwait City, Kanpur, Los Angeles, Coimbatore, Vadodara, Thane, Ludhiana, Edmonton, Mumbai, Granada, Faridabad, Singapore, Montreal, Muscat, Abu Dhabi, Geoje-si, Ranchi, Chennai, Bengaluru, Madrid, Lahore, Thiruvananthapuram, Tehran, Ernakulam, Chiyoda, Seoul, Howrah, Algiers, Istanbul, Colombo, Atyrau, Doha, Gimhae-si, Jaipur, Indore, Manama, Navi Mumbai, Jakarta, Pimpri-Chinchwad, Hong Kong, Caracas, Ahvaz, Mexico City, Dubai, Lagos, Perth, Ulsan, Aberdeen, Melbourne, La Victoria, Pune, Noida, Jeddah, Petaling Jaya, Haryana, Santiago, Ho Chi Minh City, Bhopal, Hyderabad, Moscow, Busan, Kazakhstan, South Africa, Portugal, Italy, United States, Singapore, Costa Rica, Libya, Philippines, Afghanistan, Trinidad & Tobago,Tunisia, Finland, Sweden, China, New Zealand, Qatar, Iran, Denmark, Vietnam, Nigeria, Tibet, Peru, Malaysia, India, Jordan, Belarus, Iraq, Ireland, Thailand, Germany, Puerto Rico, Belgium, Mongolia, Greece, Kuwait, Pakistan, Zimbabwe, Ukraine, Canada, Azerbaijan, Romania, Ecuador, Hong Kong, Macau, Gambia, Norway, Namibia, Algeria, Australia, Oman, Bulgaria, Saudi Arabia, United Arab Emirates, France, Austria, Argentina, Mexico, Czech Republic, Iran, Russia, Nepal, Mexico, Yemen, Hungary, Serbia, Estonia, Turkey, Lebanon, Colombia, Slovakia, Taiwan, Kenya, Chile, Switzerland, Sri Lanka, Netherlands, United Kingdom, Egypt, Bahrain, Chile, Bhutan, Nigeria, Brazil, Bolivia, Bangladesh, Venezuela, Lithuania, Angola, Poland, Morocco, Japan, Gabon, Israel, Ghana, South Korea, Croatia, Poland, Spain, Indonesia.