Stainless Steel Products

310H stainless steel Valve/ ASTM A351 UNS S31009 SS Valves

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

ASTM A249 TP 310H SS Seamless Pipes Manufacturer, SS 310H Instrument Monoflange Valves, 310H SS Seamless Valves, Stainless Steel 310H Black Round Tubes Exporter, Stainless Steel 310H Instrument Manifolds Valves Supplier in India.

ASTM A312 SS TP 310H Round Pipes, Stainless 310H Valves Manufacturer In India, ASTM A276 310H SS Instrumentation Valves, SS UNS S31009 Pipes Valves Suppliers, 310H Stainless Steel Integral-Bonnet Instrument Needle Valves Exporter in India.

Detailed Information

Prashaant Steel & Alloys is a maker of 310H Stainless Steel Valves of exceptional quality. The SS UNS S31009 Valves that we manufacture are highly common due to their superior quality. Prashaant Steel & Alloys has a production facility that is well-equipped with cutting-edge technology, allowing us to manufacture industry-recognized ASTM A240 SS 310H Valves. We believe in customer loyalty at Prashaant Steel & Alloys, and we aim to satisfy our customers’ expectations and demands in terms of both quality and quantity. Our wide inventory allows us to easily meet bulk orders for our customers. We export our goods to countries all over the world, and we store our UNS S31009 SS Valves in durable wooden boxes to prevent loss during transit. Many of the required documentation is also included in our packaging. Raw Materials Stamp, 100% Radiography Examination Report, Third Party Inspection Report, and other records are included with our SS 310H Valves. Mechanical tests, pitting resistance tests, flaring tests, flattening tests, bent tests, positive content recognition tests, intergranular corrosion tests, and micro and macro tests are some of the relevant tests performed on Stainless Steel 310H Valves. They’re dependable, and upkeep isn’t prohibitively costly. The joining of two or three pipes is a common procedure. The SS UNS S31009 Valves are used to secure the end of a pipe. They have a stunning finish with flat corners. Their height is moderate and tolerable. Customers will be able to purchase these Stainless Steel 310H Valves at affordable prices, as well as in a range of shapes, sizes, and thicknesses.

The carbon is present in 0.08% proportion. Nickel holds 22% share in the whole constitution. 1.50% is the portion of silicon in the 310H Valves. The maximum percentage of sulfur is 0.03. Manganese holds 2% which is the maximum percentage of its existence. Phosphorus is 0.045%, which is the maximum percentage of its presence. Chromium is 26% and is the highest constitution in the alloy. The physical properties are extensive and which provide it the inbuilt strength and leads to its being favorite in industries. Tensile strength is 515 MPa, which makes it endure high pressures. It can elongate up to 40% in 50mm which is good enough and is used in manufacturing hubs.

310H Stainless Steel Valves are used in industries such as food processing machinery, especially in the production of wine and beer brewing. Chemical tubes, including those for storage, are made of Stainless Steel 310H Valves. Stainless Steel 310H Valves are also used in the manufacturing of kitchen machines and appliances. 310H Valves of Stainless Steel are also used to produce threaded fasteners.

To maintain the quality specifications of UNS S31009 SS Valves, Prashaant Steel & Alloys issues documentation such as fumigation certificates, raw materials certificates, inventory traceability reports, and so on. Both orders are delivered in compliance with the needs of the customers. To ensure only high-quality outputs, we at Prashaant Steel & Alloys perform extreme quality tests. Hardness test, flattening test, mechanical testing such as area tensile, etc. are some of the tests we perform on SS 310H Valves.

Stainless Steel 310H Valves Specification:

| Specifications | ASTM A403 / ASME SA403 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Size | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Type | Seamless / Welded / Fabricated |

| Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

ASTM A276 310H Instrumentation Valves Chemical Composition:

| Grade | C | Mn | Si | P | S | Cr | Ni |

| SS 310H | 0.04 – 0.10 | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 |

ANSI B16.34 SS 310H Instrumentation Valves Mechanical Properties:

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

TP 310H Stainless Steel Valves Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS |

| SS 310H | 1.4301 | S31009 |

Types of Stainless Steel 310H Instrumentation Valves:

- UNS S31009 Solenoid Instrument Valve Manifold

- SS 310H Integral-Bonnet Instrument Needle Valves

- SS 310H Two piece Instrument Ball Valves

- 1.4301 Instrument Trunnion Ball Valves

- ANSI B16.34 SS 310H DBB Valve

- SS 310H Metering Valve Exporter

- SS 1.4301 Instrumentation Valves Dealer

- Stainless Steel S31009 Instrumentation Valves

- UNS S31009 Bellows-sealed Valves

- SS 1.4301 Fluid Line Stop Valves

- SS 310H Cryogenic Safety Relief Valves Supplier

- SUS 310H O-Ring Poppet Valve

- UNS S31009 3-Way Manifold Valves

- Stainless Steel 310H Rising Plug Valves

- ASME SA 276 SS 310H In-Line Gauge Isolator Valves

- 1.4301 In-line Push-to-Read Gauge Isolator Valve

Our Products

Our Blogs

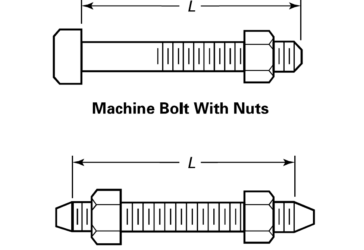

Flange Bolt Dimensions Chart and Stud Size in mm

I have discussed stud and bolt sizes used in plumbing in this article, along with a flange bolt dimension chart. The ASME B16.5 and B16.47 flange standards...