Carbon Steel Products

ASTM A105 Carbon Steel Flanges Supplier & Manufacturers

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

Carbon Steel ASME SA105 Weld Neck Flange and Blind Flange manufacturer in India, ASTM A105 Pipe Flanges, ASTM A105 N Screwed Flanges, Hot sale – check ASME SA105 Nipo Flanges Price in India.

Detailed Information

Prashaant Steel & Alloys is a leading producer of Carbon steel ASME SA105N Blind Flanges and a high-caliber retailer. Thanks to their excellent resistivity properties, the Carbon steel ASME SA105N Blind Flanges that we manufacture are extremely popular in the industry. We are considered to have the excellent quality of Carbon steel ASME SA105N Blind Flanges at Prashaant Steel & Alloys, which is why we use the highest quality of the raw materials used in the production processes. The Carbon steel ASME SA105N Blind Flanges provide outstanding resistance to corrosion and oxidation, which opens its doors to a wide range of applications.

ASTM A105 Flange is a specification of flanges. The specification can include different grades of stainless steel material made of flanges. The flanges are of forged carbon steel and are meant for high-temperature services. Prashaant Steel & Alloys is a leading manufacturer and supplier of the ASTM A105 Flange types.

While heat treating the ASTM a105n weld neck flanges is not a mandatory requirement, except for flanges above Class 300, the a105 pipe flange of special design (where the design pressure or design temperature for the carbon steel a105 reducing flange are not known. This also holds true for items over 4” NPS and above Class 300. When the a105 carbon steel plate flanges require heat treatment, processes like annealing, normalizing, normalizing and temper, normalizing and quenching, and tempering shall be applied to the forged carbon steel Astm a105.

Forgings for this specification ASTM a105 150 flange dimensions are limited up to 10,000 lbs. The ASTM a105 flange material alloy is forged at between 1,700 °F and 2,200 °F, followed by quenching and tempering the ASTM a105 class 300 flange. Forged parts of the carbon steel grade a105 are first allowed to cool down to a temperature below 1,000 °F. After cooling down the ASTM a105 flange, it is then reheating to a temperature range between 1,550 °F and 1,700 °F. Once the carbon steel a105 blind flange has been reheated, the alloy is cooled slowly in the furnace.

ASTM A105 Carbon Steel Flanges Specification

| Specifications | A105 Carbon Steel Flanges |

|---|---|

| ASME B16.5 A105 Carbon Steel Flanges size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| A105 Carbon Steel Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| A105 Carbon Steel Flanges Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| A105 Carbon Steel Flanges Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| A105 Carbon Steel Flanges Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| A105 Carbon Steel Flanges Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| A105 Carbon Steel Flanges Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| A105 Carbon Steel Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

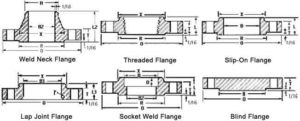

1) ANSI B16.5, ASME B16.47 FLANGE

- Size range: 1/2″ to 80″ DN15 to DN2000

- Design: welding neck, slip on, blind, socket welding, threaded, lap-joint

- Pressure: 150#, 300#, 600#,900#,1500#, 2500#

- Wall thickness for welding neck flange: STD, SCH40, SCH80, SCH160. SCH XXS

- Material: carbon steel A105, stainless steel 304/304L, 316/316L

- Coating: black paint, yellow transparent paint, cold and hot dip galvanize

- Package: seaworthy plywood case, wooden pallet

2) EN1092-1 FLANGE

- Size range: DN15 to DN2000 Design: type: 01 plate flange, type02 loose flange, type05 blind flange, type11 welding necking

- type12 slip on flange, type 13 threaded flange

- Pressure: PN6, PN10, PN16, PN25, PN40, PN64, PN100

- Material: carbon steel C22.8, S235, S235JR, P235GH, stainless steel: 304/304L, 316/316L

- Coating: black paint, yellow transparent paint, cold and hot dip galvanize

- Package: seaworthy plywood case, wooden pallet

3) DIN FLANGE

- Size range: DN15 to DN2000

- Design: slip on flange DIN 2573,2576,2502,2503, 2543,2545

- welding neck flange DIN 2631, 2632,2633,2634,2635

- blind flange DIN 2527 PN6, PN10, PN16, PN25, PN40

- threaded flange DIN 2565,2566,2567,2567

- loose flange DIN 2641,2642,2656,2673

- Material: carbon steel ST37.2, stainless steel 1.4301, 1.4404

- Coating: rust-proof oil, transparent paint, cold and hot galvanize

- Package: seaworthy plywood case, wooden pallet

ASTM A105 Pipe Flanges Chemical Formula:

| ELEMENT | COMPOSITION, % |

| Carbon | 0.35 max |

| Manganese | 0.60-1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10-0.35 |

| Copper | 0.40 max (1) |

| Nickel | 0.40 max (1) |

| Chromium | 0.30 max (1-2) |

| Molybdenum | 0.12 max (1-2) |

| Vanadium | 0.08 max |

ASTM A105 N Screwed Flanges Mechanical Analysis:

| MECHANICAL PROPERTIES | REQUIREMENTS |

| Tensile strength,min,psi [MPa] | 70000 [485] |

| Yield strength,min,psi [MPa] | 36000 [250] |

| Elongation, min, % | 30 |

| Reduction Of Area,min,% | 30 |

| Hardness,HB,max | 187 |

ASME SA105n Socket Weld Flanges Physical Properties

|

Density (lb / cu. in.)

|

0.284

|

|

Specific Gravity

|

7.9

|

|

Specific Heat (Btu/lb/Deg F – [32-212 Deg F])

|

0.107

|

|

Melting Point (Deg F)

|

2740

|

|

Thermal Conductivity

|

360

|

|

Mean Coeff Thermal Expansion

|

6.7

|

|

Modulus of Elasticity Tension

|

30

|

|

Modulus of Elasticity Torsion

|

11

|

Size Inch to MM A105 Class 300 Flange

| Nominal Size | Outside Diameter (OD) | Bore Diameter (B) | No. of Bolt Holes | Bolt Hole Diam. | Bolt Circle (BC) | Thickness (T) | Hub Length (L) | Hub Diam. (H) | Lap Radius ( R ) | Approx. Weight (lbs) |

| 1 | 4.25 | 1.38 | 4 | 0.625 | 3.13 | 0.563 | 0.688 | 1.938 | 0.13 | 2 |

| 1 1/4 | 4.68 | 1.72 | 4 | 0.625 | 3.50 | 0.625 | 0.813 | 2.312 | 0.19 | 3 |

| 1 1/2 | 5.00 | 1.97 | 4 | 0.625 | 3.88 | 0.688 | 0.875 | 2.563 | 0.25 | 3 |

| 2 | 6.00 | 2.46 | 4 | 0.750 | 4.75 | 0.750 | 1.000 | 3.063 | 0.31 | 5 |

| 2 1/2 | 7.00 | 2.97 | 4 | 0.750 | 5.50 | 0.875 | 1.125 | 3.563 | 0.31 | 7 |

| 3 | 7.50 | 3.60 | 4 | 0.750 | 6.00 | 0.938 | 1.188 | 4.250 | 0.38 | 8 |

| 3 1/2 | 8.50 | 4.10 | 8 | 0.750 | 7.00 | 0.938 | 1.250 | 4.812 | 0.38 | 11 |

| 4 | 9.00 | 4.60 | 8 | 0.750 | 7.50 | 0.938 | 1.312 | 5.312 | 0.44 | 13 |

| 5 | 10.00 | 5.69 | 8 | 0.875 | 8.50 | 0.938 | 1.438 | 6.438 | 0.44 | 15 |

| 6 | 11.00 | 6.75 | 8 | 0.875 | 9.50 | 1.000 | 1.562 | 7.562 | 0.50 | 18 |

| 8 | 13.50 | 8.75 | 8 | 0.875 | 11.75 | 1.125 | 1.750 | 9.688 | 0.50 | 30 |

| 10 | 16.00 | 10.92 | 12 | 1.000 | 14.25 | 1.188 | 1.938 | 12.000 | 0.50 | 42 |

| 12 | 19.00 | 12.92 | 12 | 1.000 | 17.00 | 1.250 | 2.188 | 14.375 | 0.50 | 64 |

| 14 | 21.00 | 14.19 | 12 | 1.125 | 18.75 | 1.375 | 2.250 | 15.750 | 0.50 | 90 |

| 16 | 23.50 | 16.19 | 16 | 1.125 | 21.25 | 1.438 | 2.500 | 18.000 | 0.50 | 98 |

| 18 | 25.00 | 18.20 | 16 | 1.250 | 22.75 | 1.562 | 2.688 | 19.875 | 0.50 | 125 |

| 20 | 27.50 | 20.25 | 20 | 1.250 | 25.00 | 1.688 | 2.875 | 22.000 | 0.50 | 160 |

| 24 | 32.00 | 24.25 | 20 | 1.375 | 29.50 | 1.875 | 3.250 | 26.125 | 0.50 | 212 |

| 30** | 38.75 | 30.25 | 28 | 1.375 | 36.00 | 2.125 | 3.500 | 32.750 | 0.50 | 305 |

| 36** | 46.00 | 36.25 | 32 | 1.625 | 42.75 | 2.375 | 3.750 | 39.250 | 0.50 | 440 |

weight chart of ASTM A105 Flange

| CLASS | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

|---|---|---|---|---|---|---|---|

| 150 lb | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Carbon Steel A105 Flange Pressure Ratings

|

TEMP

°C |

150

|

300

|

400

|

600

|

900

|

1500

|

2500

|

|

-29 TO 38

|

19.6

|

51.1

|

68.1

|

102.1

|

153.2

|

255.3

|

425.5

|

|

50

|

19.2

|

50.1

|

66.8

|

100.2

|

150.4

|

250.6

|

417.7

|

|

100

|

17.7

|

46.6

|

62.1

|

93.2

|

139.8

|

233

|

388.3

|

|

150

|

15.8

|

45.1

|

60.1

|

90.2

|

135.2

|

225.4

|

375.6

|

|

200

|

13.8

|

43.8

|

58.4

|

87.6

|

131.4

|

219

|

365

|

|

250

|

12.1

|

41.9

|

55.9

|

83.9

|

125.8

|

209.7

|

349.5

|

|

300

|

10.2

|

39.8

|

53.1

|

79.6

|

119.5

|

199.1

|

331.8

|

|

325

|

9.3

|

38.7

|

51.6

|

77.4

|

116.1

|

193.6

|

322.6

|

|

350

|

8.4

|

37.6

|

50.1

|

75.1

|

112.7

|

187.8

|

313

|

|

375

|

7.4

|

36.4

|

48.5

|

72.7

|

109.1

|

181.8

|

303.1

|

|

400

|

6.5

|

34.7

|

46.3

|

69.4

|

104.2

|

173.6

|

289.3

|

|

425

|

5.5

|

28.8

|

38.4

|

57.5

|

86.3

|

143.8

|

239.7

|

|

450

|

4.6

|

23

|

30.7

|

46

|

69

|

115

|

191.7

|

|

475

|

3.7

|

17.4

|

23.2

|

34.9

|

52.3

|

87.2

|

145.3

|

|

500

|

2.8

|

11.8

|

15.7

|

23.5

|

35.3

|

58.8

|

97.9

|

|

538

|

1.4

|

5.9

|

7.9

|

11.8

|

17.7

|

29.5

|

49.2

|

|

TEMP

°C |

150

|

300

|

400

|

600

|

900

|

1500

|

2500

|

Carbon Steel A105 Flange Dimensions

150 LB Flange Dimensions

300 LB Flange Dimensions

600 LB Flange Dimensions

900 LB Flange Dimensions

1500 LB Flange Dimensions

2500 LB Flange Dimensions

DIN 2527 Flanges

DIN 2573 Flanges

DIN 2576 Flanges

DIN 2632 Flanges

DIN 2633 Flanges

DIN 2635 Flanges

DIN 2642 Flanges

ANSI B16.47 Flange

A105 Carbon Steel Pipe Flange Dimensions

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

ASTM A105 Carbon Steel Flanges Available Types:

| Carbon Steel Flanges | Carbon Steel EN 1092-1 Flanges |

| Carbon Steel BS 4504 Flanges | Carbon Steel A105N Forged Flanges |

| Carbon Steel A105 Flanges | Carbon Steel Slip on Flanges |

| Carbon Steel Flat Flange Suppliers | ANSI Carbon Steel Blind Flange |

| Carbon Steel A105N Weld Neck Flanges Dealer | Carbon Steel Socket weld Flanges Exporter |

| Carbon Steel Long Weld Neck Flanges Stockholder | CS ASTM A105 Threaded Flanges Distributors |

| Carbon Steel ASTM A105 Reducing Flanges | Carbon Steel Ring Type Joint Flanges Manufacturer |

| Carbon Steel A105 Orifice Flange | ASTM A105 Carbon Steel Spectacle Blind Flanges |

| ASME SA105 Carbon Steel WNRF Flange | Carbon ASTM A105N SORF Flanges |

| ANSI B16.5 Carbon Steel RTJ Flanges | Carbon Steel Screwed Flanges Stockist |

| ASTM A105N Carbon Steel Lap Joint Flanges | ASME SA105 Carbon Steel BLRF Flange |

| Carbon Steel Raised Face Flanges | ASTM A105 Carbon Steel Nipoflange |

| A105 Carbon Steel Square Flanges | ASME SA105N Carbon Steel SWRF Flange |

| Steel Tongue & Groove Flanges | Carbon Steel Male & Female Flanges |

| A105 Carbon Steel DIN Flanges | Carbon Steel ASME B16.5 Flanges |

Our Products

CITIES WE DELIVER

Rajkot, New Delhi, Chandigarh, Bogota, Bangkok, Secunderabad, Rio de Janeiro, Hanoi, Dallas, Courbevoie, Kuala Lumpur, Al Jubail, Dammam, Nagpur, Gurgaon, Sydney, Ankara, Karachi, London, Sharjah, Calgary, Visakhapatnam, Toronto, Vung Tau, Riyadh, Brisbane, Nashik, Milan, Port-of-Spain, Kolkata, Surat, Houston, Baroda, Cairo, Jamshedpur, New York, Ahmedabad, Al Khobar, Kuwait City, Kanpur, Los Angeles, Coimbatore, Vadodara, Thane, Ludhiana, Edmonton, Mumbai, Granada, Faridabad, Singapore, Montreal, Muscat, Abu Dhabi, Geoje-si, Ranchi, Chennai, Bengaluru, Madrid, Lahore, Thiruvananthapuram, Tehran, Ernakulam, Chiyoda, Seoul, Howrah, Algiers, Istanbul, Colombo, Atyrau, Doha, Gimhae-si, Jaipur, Indore, Manama, Navi Mumbai, Jakarta, Pimpri-Chinchwad, Hong Kong, Caracas, Ahvaz, Mexico City, Dubai, Lagos, Perth, Ulsan, Aberdeen, Melbourne, La Victoria, Pune, Noida, Jeddah, Petaling Jaya, Haryana, Santiago, Ho Chi Minh City, Bhopal, Hyderabad, Moscow, Busan, Kazakhstan, South Africa, Portugal, Italy, United States, Singapore, Costa Rica, Libya, Philippines, Afghanistan, Trinidad & Tobago,Tunisia, Finland, Sweden, China, New Zealand, Qatar, Iran, Denmark, Vietnam, Nigeria, Tibet, Peru, Malaysia, India, Jordan, Belarus, Iraq, Ireland, Thailand, Germany, Puerto Rico, Belgium, Mongolia, Greece, Kuwait, Pakistan, Zimbabwe, Ukraine, Canada, Azerbaijan, Romania, Ecuador, Hong Kong, Macau, Gambia, Norway, Namibia, Algeria, Australia, Oman, Bulgaria, Saudi Arabia, United Arab Emirates, France, Austria, Argentina, Mexico, Czech Republic, Iran, Russia, Nepal, Mexico, Yemen, Hungary, Serbia, Estonia, Turkey, Lebanon, Colombia, Slovakia, Taiwan, Kenya, Chile, Switzerland, Sri Lanka, Netherlands, United Kingdom, Egypt, Bahrain, Chile, Bhutan, Nigeria, Brazil, Bolivia, Bangladesh, Venezuela, Lithuania, Angola, Poland, Morocco, Japan, Gabon, Israel, Ghana, South Korea, Croatia, Poland, Spain, Indonesia.