Introduction

Around 500 BC, the first hydrocarbon pipelines were discovered in China. They were constructed of bamboo. This technology has advanced substantially since then. The first oil pipeline in the United States is thought to have been erected in Pennsylvania in 1862. There are about 2.6 million miles of oil and gas pipelines in the United States today.

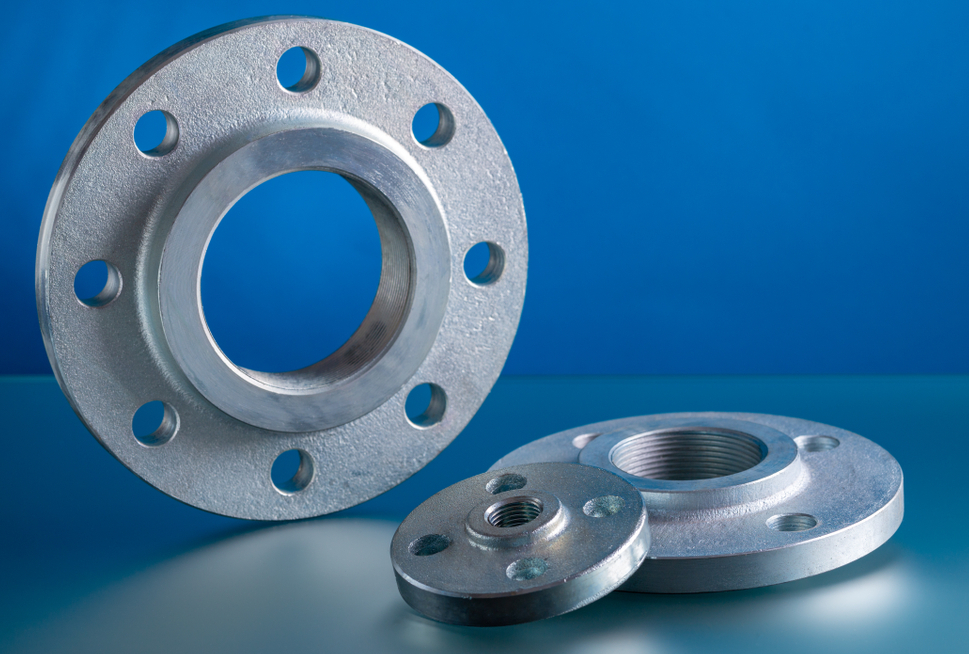

Depending on the function, size, and environmental criteria of a given application, several materials are used to construct oil and gas pipelines. Stainless steel, nickel alloys, and plastics are among these materials. For oil rigs and piping systems, stainless steel is the most popular material. As a result, the majority of fittings, including flanges, are made of steel.

The following are seven advantages of stainless steel flange fittings.

1. CORROSION RESISTANCE

Internal corrosion in piping systems is frequently caused by liquid and gas flow in oil pipelines. Corrosion is still a major hazard in the oil and gas industry, costing the US economy about $9 billion each year. In comparison to other metals, stainless steel has a strong corrosion resistance. This makes it an excellent material for pipe flanges and fittings.

2. VERSATILITY

Stainless steel has a wide range of applications. To improve the qualities of stainless steel, different elements such as nickel, molybdenum, or nitrogen can be added. You may acquire stainless steel flanges for a range of applications by using standard dimensions and requirements. This enables the pipe flanges to be used in a wider range of interior and outdoor applications.

3. STRENGTH

A system’s strength is only as strong as its weakest component. Weld fittings and joints have long been considered weak spots in liquid and gas flow equipment. Its tensile strength is increased by the inclusion of titanium and molybdenum, which reduces the risk of warping or distortion. Aluminum, for example, is a soft metal that may not operate under high heat or pressure.

4. TEMPERATURE AND PRESSURE TOLERANCE

Stainless steel flange fittings, depending on the metal grade, can tolerate high pressure and temperatures. Flanges made to ASTM A182 may withstand temperatures ranging from 500 to 800 degrees Celsius. The ASTM, API, or ANSI classifications may be a good starting point for determining the appropriate pressure class for your application.

5. VALUE

Stainless steel fittings are extremely long-lasting. Pipe flanges can last for decades, allowing liquid and gas to flow freely throughout your piping system. Stainless steel is a durable and easy-to-maintain material. Because of its stain and corrosion resistance, you may not need to repair the industrial long weld neck flanges for many years.

6. SUSTAINABILITY

Flange fittings made of stainless steel have a naturally gleaming and attractive appearance. To protect the flanges from corrosion, you may not need to coat or line them. In the long run, this makes this material a more environmentally friendly option. Furthermore, if you decide to replace your bolts and flanges, this metal is 100% recyclable. Approximately half of all stainless steel manufactured in the United States is made from recycled scrap metal, thus these flange fittings can help you minimise your project’s overall carbon footprint.

7. EASY INSPECTION

Pipe flanges that connect equipment and valves give a convenient access point for cleaning and maintenance. The flanges are easy to check, modify, or clean since they are made of stainless steel, which resists rust and corrosion. This can help you save time and money in the long run.

When choosing pipe flanges, one of the most important considerations is the material. Because stainless steel is a strong, durable, and corrosion-resistant metal, it’s a great choice for oil and gas flange fittings. Contact Us if you wish to take advantage of Flanges.

Read More :

Flanges used in Piping Applications : Know more about different types of flanges used in Piping Applications

Recent Comments