Types of Flanges Manufacturer And Supplier

Flanges|Flanges Supplier | Flanges Manufacturer in India | Different Types of Flanges Flanges Price in India | SS Flanges Exporter| Blind Flanges| Slip-on Flanges | Lap Joint Flanges | Threaded Flanges | Weld Neck Flanges| Socket Weld Flanges | All Types of Flanges Available

Flanges play a crucial role in various industrial applications, connecting pipes and facilitating the flow of liquids and gasses. Choosing the right flange supplier and manufacturer is essential for ensuring the quality, durability, and performance of your system. In this regard, Prashaant Steel & Alloys stands out as a reliable provider of flanges and other steel products.

With years of experience and a commitment to excellence, Prashaant Steel & Alloys is a trusted source for flanges in various materials and specifications. From carbon steel and stainless steel to alloy steel and other materials, the company offers a wide range of flanges to meet the demands of different applications

One of the key strengths of Prashaant Steel & Alloys is its ability to manufacture custom flanges that meet specific customer requirements. Whether you need flanges in a specific size, thickness, or material, the company has the expertise to deliver exactly what you need. This level of customization ensures that your flanges are perfectly suited to your specific system and application.

In addition to high-quality flanges, Prashaant Steel & Alloys is known for its exceptional customer service. The company’s team of experts is available to assist you with all aspects of your flange needs, from selecting the right product to ensuring that it is delivered on time and at the right price. Whether you are looking for a reliable flange supplier for a new project or need to replace worn or damaged components, Prashaant Steel & Alloys is here to help.

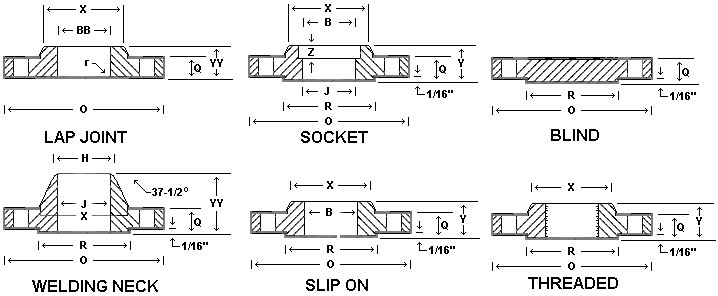

We make five of the most popular types of flanges: Nozzle Flanges, Weld Neck Flanges, Threaded Flanges, Slip On Flanges, and Blind Flanges. Flanges are used in many industries, such as petrochemical plants, refineries, pharmaceutical plants, oil and gas transportation, power generation, marine, and wastewater treatment plants, among others. Steel Flange is a plate that can be used to cover or close the end of a pipe. We call this a blind flange.

So if you are looking for a flange supplier and manufacturer that offers quality, reliability, and exceptional customer service, look no further than Prashaant Steel & Alloys. Contact the company today to learn more about its flange products and services.

Types Of Flanges

Different Types of Flanges Specification

| Flanges Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flanges Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Flanges |

| Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Flanges |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Flanges |

| Most common types of Flanges | Forged / Threaded / Screwed / Plate |

| Flanges Manufacturers in india |

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Flanges Uses & application |

|

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| JIS Flanges | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Flanges |

| UNI Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Flanges |

| EN Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Flanges |

| Connect Type/ Flanges Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Flanges Special design |

As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|

| F1 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F5 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F9 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

| F11 | 0.5-0.15 | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 1.0-1.5 | 0.44-0.65 |

| F12 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F22 | 0.50.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| F91 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

Flanges Mechanical Properties

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|

| F1 | 275 | 485 | 20 % |

| F5 | 275 | 485 | 20 % |

| F9 | 380 | 585 | 20 % |

| F11 | 205 | 415 | 20 % |

| F12 | 275 | 485 | 20 % |

| F22 | 205 | 415 | 20 % |

| F91 | 380 | 585 | 20 % |

Flanges Dimensions

| DN (inch) |

Dimension | ANSI B16.5 Flange Dimensional Sizes 3 to 10 inches Table Chart | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 125 lbs 150 lbs |

300 lbs | 400 lbs | 600 lbs | 900 lbs | 1500 lbs | 2500 lbs | ||||||||||

| inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | |||

| 3 | A | 7 1/2 | 190.5 | 81/4 | 209.6 | 81/4 | 209.6 | 8 1/4 | 209.6 | 9 1/2 | 241 | 10 1/2 | 267 | 12 | 305 | |

| b | 15/16 | 23.8 | 1 1/8 | 28.6 | 11/4 | 31.8 | 1 1/4 | 31.8 | 1 1/2 | 38.1 | 1 7/8 | 47.6 | 2 5/8 | 66.7 | ||

| D2 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | ||

| D1 | 6 | 152.4 | 6 5/8 | 168.3 | 6 5/8 | 168.3 | 6 5/8 | 168.3 | 71/2 | 190.5 | 8 | 203 | 9 | 228.6 | ||

| n | 4 | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 7/8 | 22.2 | 7/8 | 22.2 | 1 | 25.4 | 1 1/4 | 31.8 | 1 3/8 | 34.9 | ||

| 3 1/2 | A | 8 1/2 | 215.9 | 9 | 228.6 | 9 | 228.6 | 9 | 228.6 | – | – | – | – | – | – | |

| b | 15/16 | 23.8 | 13/16 | 30.2 | 13/8 | 34.9 | 13/8 | 34.9 | – | – | – | – | – | – | ||

| D2 | 5 1/2 | 139.7 | 5 /2 | 139.7 | 5 1/2 | 139.7 | 5 1/2 | 139.7 | – | – | – | – | – | – | ||

| D1 | 7 | 177.8 | 7 1/4 | 184.2 | 7 1/4 | 184.2 | 7 1/4 | 184.2 | – | – | – | – | – | – | ||

| n | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | – | – | – | – | – | – | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 1 | 25.4 | 1 | 25.4 | – | – | – | – | – | – | ||

| 4 | A | 9 | 228.6 | 10 | 254 | 10 | 254 | 10 3/4 | 273 | 11 1/2 | 292 | 12 1/4 | 311 | 14 | 356 | |

| b | 15/16 | 23.8 | 1 1/4 | 31.7 | 1 3/8 | 34.9 | 1 1/2 | 38.1 | 1 3/4 | 44.4 | 2 1/8 | 54 | 3 | 76.2 | ||

| D2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | ||

| D1 | 7 1/2 | 190 | 7 7/8 | 200 | 7 7/8 | 200 | 8 1/2 | 215.9 | 9 1/4 | 235 | 9 1/2 | 241 | 10 3/4 | 273 | ||

| n | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 1 | 25.4 | 1 | 25.4 | 1 1/4 | 31.8 | 1 3/8 | 34.9 | 1 5/8 | 41.3 | ||

| 5 | A | 10 | 254 | 11 | 279.4 | 11 | 279.4 | 13 | 330.2 | 13 3/4 | 349 | 14 3/4 | 375 | 16 1/2 | 419 | |

| b | 1 5/16 | 23.8 | 13/8 | 34.9 | 1 1/2 | 38.1 | 1 3/4 | 44.4 | 2 | 50.8 | 2 7/8 | 73 | 3 5/8 | 92.1 | ||

| D2 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | ||

| D1 | 8 1/2 | 215.9 | 9 1/4 | 234.9 | 9 1/4 | 234.9 | 10 1/2 | 266.7 | 11 | 279 | 11 1/2 | 292 | 12 3/4 | 324 | ||

| n | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 7/8 | 22.2 | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 3/8 | 34.9 | 1 5/8 | 41.3 | 1 7/8 | 47.6 | ||

| 6 | A | 11 | 279 | 12 1/2 | 317.5 | 12 1/2 | 317.5 | 14 | 355.6 | 15 | 381 | 15 1/2 | 394 | 19 | 483 | |

| b | 1 | 25.4 | 17/16 | 36.5 | 1 5/8 | 41.3 | 1 7/8 | 47.6 | 2 3/16 | 55.6 | 3 1/4 | 82.6 | 4 1/4 | 108 | ||

| D2 | 8 1/2 | 216 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 216 | ||

| D1 | 9 1/2 | 241 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 11 1/2 | 292.1 | 12 1/2 | 318 | 12 1/2 | 318 | 14 1/2 | 368 | ||

| n | 8 | 8 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 8 | 8 | ||

| d | 7/8 | 22.2 | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | 1 1/2 | 38.1 | 2 1/8 | 54 | ||

| 8 | A | 13 1/2 | 342.9 | 15 | 381 | 15 | 381 | 16 1/2 | 419 | 18 1/2 | 470 | 19 | 482.6 | 21 3/4 | 552 | |

| b | 1 1/8 | 28.6 | 1 5/8 | 41.3 | 1 7/8 | 47.6 | 2 3/16 | 55.6 | 2 1/2 | 63.5 | 3 5/8 | 92.1 | 5 | 127 | ||

| D2 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | ||

| D1 | 11 3/4 | 298.4 | 13 | 330.2 | 13 | 330.2 | 13 3/4 | 349.2 | 15 1/2 | 394.2 | 15 1/2 | 394.2 | 17 1/4 | 438 | ||

| n | 8 | 8 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| d | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | 1 1/2 | 38.1 | 1 3/4 | 44.5 | 2 1/8 | 54 | ||

| 10 | A | 16 | 406.4 | 17 1/2 | 444.5 | 17 1/2 | 444.5 | 20 | 508 | 21 1/2 | 546 | 23 | 584 | 26 1/2 | 673 | |

| b | 1 3/16 | 30.2 | 1 7/8 | 47.6 | 2 1/8 | 54 | 2 1/2 | 63.5 | 2 3/4 | 69.8 | 4 1/4 | 108 | 6 1/2 | 165 | ||

| D2 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | ||

| D1 | 14 1/4 | 361.9 | 15 1/4 | 387.4 | 15 1/4 | 387.4 | 17 | 431.8 | 18 1/2 | 470 | 19 | 482.6 | 21 1/4 | 540 | ||

| n | 12 | 12 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 12 | 12 | 12 | 12 | ||

| d | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | 1 3/8 | 34.9 | 1 1/2 | 38.1 | 2 | 50.8 | 2 5/8 | 66.7 | ||

Flange Weight Chart

| Flange Weights by Pressure Class and Size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | 150 # | 300 # | 600 # | 900 # | 1500 # | 2500 # | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1/2″ | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | SEE 1500 # WEIGHTS | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4″ | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | SEE 1500 # WEIGHTS | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1″ | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | SEE 1500 # WEIGHTS | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2″ | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | SEE 1500 # WEIGHTS | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2″ | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | SEE 1500 # WEIGHTS | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2″ | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | SEE 1500 # WEIGHTS | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3″ | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4″ | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5″ | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6″ | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8″ | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10″ | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12″ | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14″ | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16″ | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18″ | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20″ | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22″ | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24″ | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

Flanges in Acc. with EN / DIN

| Type | EN | DIN |

|---|---|---|

| Weld Neck Flanges | 11 | 2627 – 2638 |

| Blind Flanges | 05 | 2527 |

| Threaded Flanges | 13 | 2558 | 2565 – 2569 |

| Flat Flanges for Welding | 01 | 2573 | 2576 |

| Loose Flanges | 02 | 2641 | 2642 | 2655 | 2656 |

| Loose Flanges | 04 | 2673 – 2676 |

| Weld-on Collars | 32 | 2641 | 2642 | 2655 | 2656 |

| Weld Neck Collars | 34 | 2673 – 2676 |

| Slip-on Flanges | 12 | 86029 | 86030 |

| Weld Flanges for Pressure Vessels | 28031 | 28033 | |

| Lapped Flanges | 86037 | |

| Welding Flanges | 86041 | |

| Exhaust gas line Flanges | 86044 | |

| Special Flanges in accordance with drawings | ||

| Flanges for automatic welding processes in acc. with PAS 1057-6 | ||

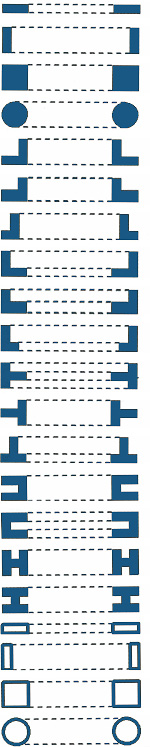

Flange versions

|

Flat steel, edgewise, as a flange |

| Flat steel, flat, as a tire | |

| square steel | |

| Round steel | |

| Angle steel, thighs outwards | |

| Angle steel, wide leg to the outside | |

| Angle steel, narrow leg to the outside | |

| Angle steel, thighs inside | |

| Angle steel, wide leg inside | |

| Angle steel, narrow leg inside | |

| T-steel, bridge inside | |

| T-steel, bridge to the outside | |

| T-steel, foot bent upright | |

| U-steel, opening to the outside | |

| U-steel, opening inwards | |

| Double-T carrier (bent around the X-axis) | |

| Double-T carrier (bent around the Y-axis) | |

| Rectangular tube, high edge | |

| Rectangular tube, flat | |

| square tube | |

| round tube |

| FLANGES | EN V-flanges type 11 according to EN 1092-1

|

ASTM WN flanges according to ANSI B16.5, ANSI B16.47 series A + B

|

|---|---|---|

| BLIND FLANGES | Type 05 according to EN 1092-1

|

ANSI B16.5, ANSI B16.47 Series A + B

|

| LOOSE FLANGES, SMOOTH FLANGES, FLARES AND COLLARS | EN 1092-1 | different pressure levels according to ANSI B16.5

|

| VARIOUS SEALING STRIP SHAPES | Form A, Form B1 / B2, Form C, Form D, Form E, Form F, Form G, Form H Linseneindrehung |

|

| MATERIAL GRADES | P250GH

|

|

Flanges Pressure Rating & Flanges Standards

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind, Socket Weld, Lap Joint, Threaded Flange, Ring Type Joint |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate, Loose Plate, Loose Plate With Weld Neck , Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Flanges Supplier in India

Because their flanges are reliable and work well, Prashaant Steel & Alloy is one of the top suppliers, dealers, manufacturers, and exporters in India. Every month, we usually send about fifty-seven containers of Flanges to Indian port for different customers.

We have sales reps in most of India’s major cities because we offer high-quality Flanges at low prices and with easy service. These cities are:

| City we supply Flanges: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

| Countries we supply and export Flanges worldwide: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

FAQ

What are flanges used for?

Flanges are used to connect pipes to each other, to valves, fittings, and to special items like strainers and pressure vessels. A “blind flange” can be made by putting a cover plate together. Flanges are joined with bolts, and gaskets or other methods are often used to seal them.

Different types of flanges

The most common flange types are

- Welding Neck Flange.

- Slip-on Flange.

- Socket Weld Flange.

- Lap Joint Flange.

- Threaded Flange.

- Blind Flange.

What is a flange?

A rib or rim for strength, guidance, or to hold something else. A pipe has a flange. A flange on a wheel is an edge of fabric that sticks out and is used to decorate clothing. A jacket with shoulder flaps.

What are standard flanges?

A flange standard describes the size, finish, type of facing, marking, material, and other technical details of flanges. The European EN 1092 series has mostly taken the place of national flange standards.