ASTM A182 Slip-On Flanges

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

Slip On Flanges, ASTM A182 Slip On Flanges, Stainless Steel Slip On Flanges, ANSI B16.5 Slip On Flanges, Steel Slip On Flanges Manufacturers, Carbon Steel Slip On Flanges, Steel Slip On Flanges Suppliers In India.

Slip On Flanges Dealer, ASTM A182 Slip On Flanges Exporter, Stainless Steel Slip On Flanges Manufacturers, ANSI B16.5 Slip On Flanges Suppliers, Steel Slip On Flanges Suppliers In India.

Detailed Information

What is a slip on flange?

The Slip on Flange is essentially a ring that is fitted over the pipe end. The face of the flange extends from the end of the pipe by a sufficient distance to allow for the application of a weld bead on the inside diameter. The outside diameter of a slip-on flange is welded on both the front and the back of the flange.

Slip on flange welding

Slip on flanges are joined to pipelines or other equipment using the slip on flange welding procedure. Slip on flanges are frequently used in piping systems to join pipes to valves, pumps, or other pieces of machinery. After attaching the slip-on flange to the pipe’s end, the pipe and flange are aligned and tack-welded together. After that, the flange is fully welded to the pipe using a filet weld all the way around the flange. Before welding, it’s crucial to check that the flange and pipe are correctly aligned because any misalignment could cause leaks or other issues. Also, the right materials and welding techniques should be used during the welding process depending on the application.

Overall, slip on flange welding is a widely used technique for joining pipes and other items in a pipeline system. To establish a solid, dependable connection, best practices should be followed.

Prashaant Steel & Alloys is known as the pinnacle in the world of metal market for the best quality Sockolets production in India. Wecan produce ASTM A182 Slip On Flanges according to the standards for materials, pressure ratings, etc. Such standards include DIN, BS, and/or ISO standards, Japanese JIS. Slip-on Flange is a flange placed over the end of the pipe that extends the flange face from the end of the pipe by a sufficient distance to remove a soiling Perle on the internal diameter. Also on the back of the flange, the outer diameter of the flange is soldered. Flanges are less costly than Socket Weld Flange and easy to fit. Often, if type B or type C ends are used, this can be used as Weld Neck Flange.

Prashaant Steel & Alloys Inc is a leading Manufacturer & Supplier of all Ferrous & Non-Ferrous Metals. As a pioneer and leader in the manufacturing industry, Prashaant Steel & Alloys is at the forefront of technology and research. We are constantly innovating, listening to the rapidly changing market and giving the consumer the best value for his money. Prashaant Steel & Alloys is one of the eminent manufacturers and exporters of high-Grade ASTM A182 Stainless Steel Slip on Flanges. Prashaant Steel & Alloys has been a professionally managed importer, stockist and supplier of ferrous and non-ferrous metals. We are capable of providing a vast range of materials, from stock, to suit your needs. Prashaant Steel & Alloys offers a commendable range of Carbon Steel Slip on Flanges, for the prestigious clients with competitive price. From highly specialized non-standard material to off the shelf items, from production to prototype, from low minimums to mill runs. Prashaant Steel & Alloys has the experience to solve your most difficult requirements.

Slip-On Flanges Specifications:

|

Size |

½” (15 NB) to 48″ (1200NB) |

|

Standard |

ANSI A182, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820 |

|

Dimensions |

ANSI A182, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA |

|

Class |

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

|

Specialize |

As per drawing |

|

Connection Type |

Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large |

|

Form |

SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc |

|

Stainless Steel |

ASTM A-479, A-182, 304, 304L,304H,304S, 316, 316L,316 Ti, 316H, 309, 310, 310S, 317L, 321, 347, 409, 410, 420, 430, 440, 446, 904L. etc. |

|

Duplex Steel |

2205, 31803, 32750, 32760, 2101, 2304. |

|

Alloy Steel |

A-182 – F5, F9, F11, F12, F21, F22 & F91 |

|

Special Grade |

Stainless Steel 17-4 PH, Alloy 800, Alloy 600. Hastelloy C276. |

|

Carbon Steel |

A 105, LF 2, Duplex Steel. |

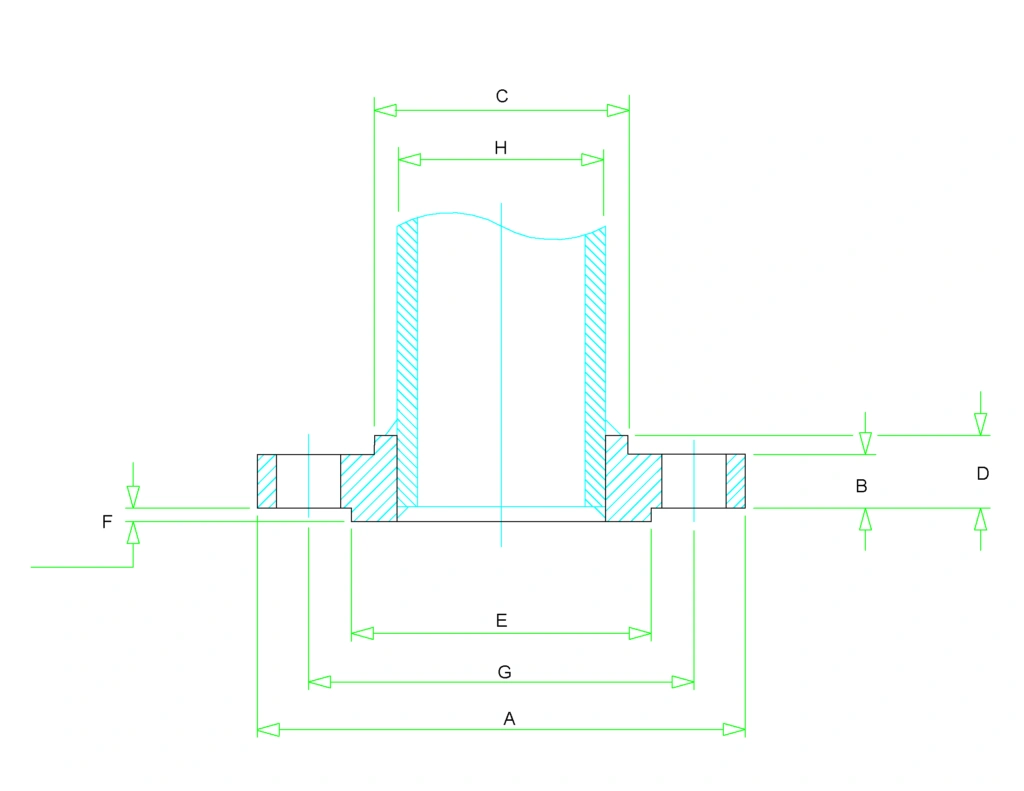

Slip On Flange Dimensions

Common outer diameters: 1/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12” to 24”.

Special made outer diameters: up to 60”.

Class range: Class 150, Class 300, 400, 600, 900, 1500, 2500(# or LB). PN 2.5 to PN 250.

Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

Slip on Flange Dimensions – Class 150 to Class 1500

Slip on flange dimensions are covered in ASME B16.5 – which covers Pipe Flanges and Flanged Fittings for size NPS ½” to 24” for above NPS 26” to 60” it should be as per ASME B16.47.

During a dimensional inspection of slip on flange, you should check for

- Outer & Inner Diameter of body

- Bolt Circle & Bolt Hole Diameter

- Length of the Hub

- Straightness and alignment of the bolt hole

Class 150 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Class 300 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 95 | 12.7 | 38 | 21 | 34.9 | 2 | 66.7 | 22.2 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.2 |

| 3/4 | 20 | 115 | 14.3 | 48 | 24 | 42.9 | 2 | 82.6 | 27.7 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 54 | 25 | 50.8 | 2 | 88.9 | 34.5 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 25 | 63.5 | 2 | 98.4 | 43.2 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 29 | 73 | 2 | 114.3 | 49.5 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 84 | 32 | 92.1 | 2 | 127 | 61.9 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 37 | 104.8 | 2 | 149.2 | 74.6 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 4.6 |

| 3 | 80 | 210 | 27 | 117 | 41 | 127 | 2 | 168.3 | 90.7 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 5.9 |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 43 | 139.7 | 2 | 184.2 | 103.4 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 7.7 |

| 4 | 100 | 255 | 30.2 | 146 | 46 | 157.2 | 2 | 200 | 116.8 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 10 |

| 5 | 125 | 280 | 33.4 | 178 | 49 | 185.7 | 2 | 235 | 144.4 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 12.7 |

| 6 | 150 | 320 | 35 | 206 | 51 | 215.9 | 2 | 269.9 | 171.4 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 17.7 |

| 8 | 200 | 380 | 39.7 | 260 | 60 | 269.9 | 2 | 330.2 | 222.2 | 12 | 7/8 | 120 | 140 | 1 | M24 | 26 |

| 10 | 250 | 445 | 46.1 | 321 | 65 | 323.8 | 2 | 387.4 | 277.4 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 36 |

| 12 | 300 | 520 | 49.3 | 375 | 71 | 381 | 2 | 450.8 | 328.2 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 52 |

| 14 | 350 | 585 | 52.4 | 425 | 75 | 412.8 | 2 | 514.4 | 360.2 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 75 |

| 16 | 400 | 650 | 55.6 | 483 | 81 | 469.9 | 2 | 571.5 | 411.2 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 86 |

| 18 | 450 | 710 | 58.8 | 533 | 87 | 533.4 | 2 | 628.6 | 462.3 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 113 |

| 20 | 500 | 775 | 62 | 587 | 94 | 584.2 | 2 | 685.8 | 514.4 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 143 |

| 24 | 600 | 915 | 68.3 | 702 | 105 | 692.2 | 2 | 812.8 | 616 | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 | 216 |

Class 400 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.5 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 104.8 | 7 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

| 4 | 100 | 255 | 35 | 146 | 51 | 157.2 | 7 | 200 | 116.1 | 8 | 7/8 | 140 | 1 | M24 | 11.8 |

| 5 | 125 | 280 | 38.1 | 178 | 54 | 185.7 | 7 | 235 | 143.8 | 8 | 7/8 | 145 | 1 | M24 | 14.1 |

| 6 | 150 | 320 | 41.3 | 206 | 57 | 215.9 | 7 | 269.9 | 170.7 | 12 | 7/8 | 150 | 1 | M24 | 20 |

| 8 | 200 | 380 | 47.7 | 260 | 68 | 269.9 | 7 | 330 | 221.5 | 12 | 1 | 170 | 1 1/8 | M27 | 31 |

| 10 | 250 | 445 | 54 | 321 | 73 | 323.8 | 7 | 387.4 | 276.2 | 16 | 1 1/8 | 190 | 1 1/4 | M30 | 42 |

| 12 | 300 | 520 | 57.2 | 375 | 79 | 381 | 7 | 450.8 | 327 | 16 | 1 1/4 | 205 | 1 3/8 | M33 | 59 |

| 14 | 350 | 585 | 60.4 | 425 | 84 | 412.8 | 7 | 514.4 | 359.2 | 20 | 1 1/4 | 210 | 1 3/8 | M33 | 82 |

| 16 | 400 | 650 | 63.5 | 483 | 94 | 469.9 | 7 | 571.5 | 410.5 | 20 | 1 3/8 | 220 | 1 1/2 | M36 | 107 |

| 18 | 450 | 710 | 66.7 | 533 | 98 | 533.4 | 7 | 628.6 | 461.8 | 24 | 1 3/8 | 230 | 1 1/2 | M36 | 130 |

| 20 | 500 | 775 | 69.9 | 587 | 102 | 584.2 | 7 | 685.8 | 513.1 | 24 | 1 1/2 | 240 | 1 3/4 | M39 | 157 |

| 24 | 600 | 915 | 76.2 | 702 | 114 | 692.2 | 7 | 812.8 | 616 | 24 | 1 3/4 | 265 | 1 7/8 | M45 | 232 |

Class 600 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 104.8 | 7 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

| 4 | 100 | 275 | 38.1 | 152 | 54 | 157.2 | 7 | 215.9 | 116.1 | 8 | 7/8 | 145 | 1 | M24 | 16.8 |

| 5 | 125 | 330 | 44.5 | 189 | 60 | 185.7 | 7 | 266.7 | 143.8 | 8 | 1 | 165 | 1 1/8 | M27 | 29 |

| 6 | 150 | 355 | 47.7 | 222 | 67 | 215.9 | 7 | 292.1 | 170.7 | 12 | 1 | 170 | 1 1/8 | M27 | 36 |

| 8 | 200 | 420 | 55.6 | 273 | 76 | 269.9 | 7 | 349.2 | 221.5 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 52 |

| 10 | 250 | 510 | 63.5 | 343 | 86 | 323.8 | 7 | 431.8 | 276.2 | 16 | 1 1/4 | 215 | 1 3/8 | M33 | 77 |

| 12 | 300 | 560 | 66.7 | 400 | 92 | 381 | 7 | 489 | 327 | 20 | 1 1/4 | 220 | 1 3/8 | M33 | 91 |

| 14 | 350 | 605 | 69.9 | 432 | 94 | 412.8 | 7 | 527 | 359.2 | 20 | 1 3/8 | 235 | 1 1/2 | M36 | 105 |

| 16 | 400 | 685 | 76.2 | 495 | 106 | 469.9 | 7 | 603.2 | 410.5 | 20 | 1 1/2 | 255 | 1 5/8 | M39 | 150 |

| 18 | 450 | 745 | 82.6 | 546 | 117 | 533.4 | 7 | 654 | 461.8 | 20 | 1 5/8 | 275 | 1 3/4 | M42 | 182 |

| 20 | 500 | 815 | 88.9 | 610 | 127 | 584.2 | 7 | 723.9 | 513.1 | 24 | 1 5/8 | 285 | 1 3/4 | M42 | 232 |

| 24 | 600 | 940 | 101.6 | 718 | 140 | 692.2 | 7 | 838.2 | 616 | 24 | 1 7/8 | 330 | 2 | M48 | 332 |

Class 900 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 120 | 22.3 | 38 | 32 | 34.9 | 7 | 82.6 | 22.2 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 44 | 35 | 42.9 | 7 | 88.9 | 27.7 | 4 | 3/4 | 115 | 7/8 | M20 | 2.3 |

| 1 | 25 | 150 | 28.6 | 52 | 41 | 50.8 | 7 | 101.6 | 34.5 | 4 | 7/8 | 125 | 1 | M24 | 3.6 |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 41 | 63.5 | 7 | 111.1 | 43.2 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 44 | 73 | 7 | 123.8 | 49.5 | 4 | 1 | 140 | 1 1/8 | M27 | 5.5 |

| 2 | 50 | 215 | 38.1 | 105 | 57 | 92.1 | 7 | 165.1 | 61.9 | 8 | 7/8 | 145 | 1 | M24 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 64 | 104.8 | 7 | 190.5 | 74.6 | 8 | 1 | 160 | 1 1/8 | M27 | 16.5 |

| 3 | 80 | 240 | 38.1 | 127 | 54 | 127 | 7 | 190.5 | 90.7 | 8 | 7/8 | 145 | 1 | M24 | 12 |

| 4 | 100 | 290 | 44.5 | 159 | 70 | 157.2 | 7 | 235 | 116.1 | 8 | 1 1/8 | 170 | 1 1/4 | M30 | 24 |

| 5 | 125 | 350 | 50.8 | 190 | 79 | 185.7 | 7 | 279.4 | 143.8 | 8 | 1 1/4 | 190 | 1 3/8 | M33 | 38 |

| 6 | 150 | 380 | 55.6 | 235 | 86 | 215.9 | 7 | 317.5 | 170.7 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 50 |

| 8 | 200 | 470 | 63.5 | 298 | 102 | 269.9 | 7 | 393.7 | 221.5 | 12 | 1 3/8 | 220 | 1 1/2 | M36 | 78 |

| 10 | 250 | 545 | 69.9 | 368 | 108 | 323.8 | 7 | 469.9 | 276.2 | 16 | 1 3/8 | 235 | 1 1/2 | M36 | 112 |

| 12 | 300 | 610 | 79.4 | 419 | 117 | 381 | 7 | 533.4 | 327 | 20 | 1 3/8 | 255 | 1 1/2 | M36 | 148 |

| 14 | 350 | 640 | 85.8 | 451 | 130 | 412.8 | 7 | 558.8 | 359.2 | 20 | 1 1/2 | 275 | 1 5/8 | M39 | 182 |

| 16 | 400 | 705 | 88.9 | 508 | 133 | 469.9 | 7 | 616 | 410.5 | 20 | 1 5/8 | 285 | 1 3/4 | M42 | 193 |

| 18 | 450 | 785 | 101.6 | 565 | 152 | 533.4 | 7 | 685.8 | 461.8 | 20 | 1 7/8 | 325 | 2 | M48 | 258 |

| 20 | 500 | 855 | 108 | 622 | 159 | 584.2 | 7 | 749.3 | 513.1 | 20 | 2 | 350 | 2 1/8 | M52 | 317 |

| 24 | 600 | 1040 | 139.7 | 749 | 203 | 692.2 | 7 | 901.7 | 616 | 20 | 2 1/2 | 440 | 2 5/8 | M64 | 608 |

Class 1500 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 120 | 22.3 | 38 | 32 | 34.9 | 7 | 82.6 | 22.2 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 44 | 35 | 42.9 | 7 | 88.9 | 27.7 | 4 | 3/4 | 115 | 7/8 | M20 | 2.3 |

| 1 | 25 | 150 | 28.6 | 52 | 41 | 50.8 | 7 | 101.6 | 34.5 | 4 | 7/8 | 125 | 1 | M24 | 3.7 |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 41 | 63.5 | 7 | 111.1 | 43.2 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 44 | 73 | 7 | 123.8 | 49.5 | 4 | 1 | 140 | 1 1/8 | M27 | 5.5 |

| 2 | 50 | 215 | 38.1 | 105 | 57 | 92.1 | 7 | 165.1 | 61.9 | 8 | 7/8 | 145 | 1 | M24 | 9.8 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 64 | 104.8 | 7 | 190.5 | 74.6 | 8 | 1 | 160 | 1 1/8 | M27 | 16.4 |

Advantages to choose the Slip On Flange

Installation costs are lower

· Less time is spent on accurately cutting the pipe

· Easier alignment

· Low hub on slip-on flanges due to pipe slips in the flange

· Interior and outer welding of flange

· Leak prevention

Flanges Applications Industries:

ASME B16.9 Degree Forged are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Degree Forged through a worldwide network of stock-keeping branches. Buttweld Forged is use in various industries like :

- Flanges uses in Paper & Pulp Companies

- Stainless Steel Flanges uses in Oil and Gas Industry

- Flanges Pipe Forged uses in Chemical Refinery

- Alloy Steel Threaded Elbows Used in Pipeline

- Buttweld Flanges Pipe Forged uses in High Temperature Application

- Flanges uses in Water Pipe Line

- ANSI B16.9 Flanges Pipe Forged can be used in Nuclear power plants

- Flanges useful for High Pressure Applications

- Flanges Long Radius Forged uses in Fabrication and welding Job

- Flanges uses in Food Processing and Dairy Industries

- Flanges Short Radius Forged uses in boiler & heat exchangers

Types of Flanges Available:

- Blind Flanges

- Slip on Flanges

- Socket Weld Flanges

- Threaded Flanges

- Weld Neck Flange

- Lap Joint Flange

- Expander Flange

- Nippo Flanges

- Reducing

Our Products

CITIES WE DELIVER

Rajkot, New Delhi, Chandigarh, Bogota, Bangkok, Secunderabad, Rio de Janeiro, Hanoi, Dallas, Courbevoie, Kuala Lumpur, Al Jubail, Dammam, Nagpur, Gurgaon, Sydney, Ankara, Karachi, London, Sharjah, Calgary, Visakhapatnam, Toronto, Vung Tau, Riyadh, Brisbane, Nashik, Milan, Port-of-Spain, Kolkata, Surat, Houston, Baroda, Cairo, Jamshedpur, New York, Ahmedabad, Al Khobar, Kuwait City, Kanpur, Los Angeles, Coimbatore, Vadodara, Thane, Ludhiana, Edmonton, Mumbai, Granada, Faridabad, Singapore, Montreal, Muscat, Abu Dhabi, Geoje-si, Ranchi, Chennai, Bengaluru, Madrid, Lahore, Thiruvananthapuram, Tehran, Ernakulam, Chiyoda, Seoul, Howrah, Algiers, Istanbul, Colombo, Atyrau, Doha, Gimhae-si, Jaipur, Indore, Manama, Navi Mumbai, Jakarta, Pimpri-Chinchwad, Hong Kong, Caracas, Ahvaz, Mexico City, Dubai, Lagos, Perth, Ulsan, Aberdeen, Melbourne, La Victoria, Pune, Noida, Jeddah, Petaling Jaya, Haryana, Santiago, Ho Chi Minh City, Bhopal, Hyderabad, Moscow, Busan, Kazakhstan, South Africa, Portugal, Italy, United States, Singapore, Costa Rica, Libya, Philippines, Afghanistan, Trinidad & Tobago,Tunisia, Finland, Sweden, China, New Zealand, Qatar, Iran, Denmark, Vietnam, Nigeria, Tibet, Peru, Malaysia, India, Jordan, Belarus, Iraq, Ireland, Thailand, Germany, Puerto Rico, Belgium, Mongolia, Greece, Kuwait, Pakistan, Zimbabwe, Ukraine, Canada, Azerbaijan, Romania, Ecuador, Hong Kong, Macau, Gambia, Norway, Namibia, Algeria, Australia, Oman, Bulgaria, Saudi Arabia, United Arab Emirates, France, Austria, Argentina, Mexico, Czech Republic, Iran, Russia, Nepal, Mexico, Yemen, Hungary, Serbia, Estonia, Turkey, Lebanon, Colombia, Slovakia, Taiwan, Kenya, Chile, Switzerland, Sri Lanka, Netherlands, United Kingdom, Egypt, Bahrain, Chile, Bhutan, Nigeria, Brazil, Bolivia, Bangladesh, Venezuela, Lithuania, Angola, Poland, Morocco, Japan, Gabon, Israel, Ghana, South Korea, Croatia, Poland, Spain, Indonesia.

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad and Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.