SABS 1123 Pipe Flanges

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

Sabs 1123 Pipe Flanges In India, Stainless Steel SABS 1123 Flanges Material Specification.

Detailed Information

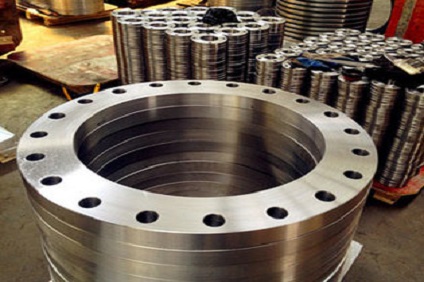

Prashaant Steel & Alloys is a well-known maker and retailer of Flanges for Stainless Steel 321 in the market. We produce ASME SA182 SS 321H Flanges that follow global and national quality requirements by using the best quality raw materials. The ASTM A182 SS 321 Flanges have a high corrosion and oxidation resistance thanks to the right mix of nickel, chromium, and titanium. Except at high temperatures, the ASME SA182 SS 321H Flanges are produced to have improved performance at low temperatures. Flanges of this kind can tolerate temperatures of up to 870 degrees Celsius. The ASTM A182 SS 321 Flanges have excellent machinability and production characteristics. Prashaant Steel & Alloys is known for manufacturing high-quality goods that match or exceed our customers’ needs. Prashaant Steel & Alloys is known for its SABS 1123 Pipe Flanges. We manufacture and sell a wide range of SABS 1123 Pipe Flanges. SABS 1123 Pipe Flanges preserve strength and corrosion resistance even when exposed to high temperatures. Flanges of this kind can tolerate temperatures of up to 870 degrees Celsius. These flanges are used for light duty applications and they are one of the older specifications available. There are other materials and specifications available to cover the Sabs 1123 Pipe Flanges Dimensions as replacements as well. Nevertheless, the SABS 1123 Table 1000 Flanges are still used with sizes ranging from ½ inches to 48 inches in the range of DN10 to DN 5000.

Sabs 1123 Class 1000 Flanges Specification:

| Size Chart | 1/2″ to 48″ |

| EN | 6Bar, 25Bar, 10Bar, 16Bar, 40Bar |

| Coating | Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized, Oil Black Paint, Anti-rust Paint, |

| Pressure Rating | Class 150, 300#, 600 LBS, Class 900, 1500#, 2500 LBS |

| ANSI Flange Standards | ANSI/EN 1092-1 |

| JIS | 5K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Production technique |

Forged, Heat treated and machined |

| Avalable Types | Lap-Joint Face (LJF), Small Male-Female (SMF), Large Tongue & Groove, , Groove, Raised Face (RF), Flat Face (FF), Large Male-Female (LMF), Ring Type Joint (RTJ), Small Tongue |

| Test | UI trasonic flaw detector, Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates |

EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / ISO |

| Uses & application |

|

Dimensions Of Sabs 1123 Table 1000/3 Flanges:

|

Nominal Bore 15 |

Flange Diameter (mm) |

PCD(mm) |

Bolts |

Boltsize |

Hole Size(mm) |

Thickness(mm) |

|

SABS1123-600/3 |

80 |

55 |

4 |

M10 |

11 |

10 |

|

SABS1123-1000/3 |

95 |

65 |

4 |

M12 |

14 |

10 |

|

SABS1123-1600/3 |

95 |

65 |

4 |

M12 |

14 |

10 |

|

SABS1123-2500/3 |

95 |

65 |

4 |

M12 |

14 |

14 |

|

SABS1123-4000/3 |

95 |

65 |

4 |

M12 |

14 |

14 |

|

Nominal Bore 20 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

90 |

65 |

4 |

M10 |

11 |

10 |

|

1123-1000 |

105 |

75 |

4 |

M12 |

14 |

10 |

|

1123-1600 |

105 |

75 |

4 |

M12 |

14 |

10 |

|

1123-2500 |

105 |

75 |

4 |

M12 |

14 |

14 |

|

1123-4000 |

105 |

75 |

4 |

M12 |

14 |

14 |

|

Nominal Bore 25 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

100 |

75 |

4 |

M10 |

11 |

10 |

|

1123-1000 |

115 |

85 |

4 |

M12 |

14 |

10 |

|

1123-1600 |

115 |

85 |

4 |

M12 |

14 |

10 |

|

1123-2500 |

115 |

85 |

4 |

M12 |

14 |

16 |

|

1123-4000 |

115 |

85 |

4 |

M12 |

14 |

16 |

|

Nominal Bore 32 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

120 |

90 |

4 |

M12 |

14 |

10 |

|

1123-1000 |

140 |

100 |

4 |

M16 |

18 |

10 |

|

1123-1600 |

140 |

100 |

4 |

M16 |

18 |

10 |

|

1123-2500 |

140 |

100 |

4 |

M16 |

18 |

18 |

|

1123-4000 |

140 |

100 |

4 |

M16 |

18 |

18 |

|

Nominal Bore 40 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

130 |

100 |

4 |

M12 |

14 |

10 |

|

1123-1000 |

150 |

110 |

4 |

M16 |

18 |

10 |

|

1123-1600 |

150 |

110 |

4 |

M16 |

18 |

10 |

|

1123-2500 |

150 |

110 |

4 |

M16 |

18 |

20 |

|

1123-4000 |

150 |

110 |

4 |

M16 |

18 |

20 |

|

Nominal Bore 50 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

140 |

110 |

4 |

M12 |

14 |

10 |

|

1123-1000 |

165 |

125 |

4 |

M16 |

18 |

10 |

|

1123-1600 |

165 |

125 |

4 |

M16 |

18 |

12 |

|

1123-2500 |

165 |

125 |

4 |

M16 |

18 |

20 |

|

1123-4000 |

165 |

125 |

4 |

M16 |

18 |

20 |

|

Nominal Bore 65 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

160 |

130 |

4 |

M12 |

14 |

10 |

|

1123-1000 |

185 |

145 |

4 |

M16 |

18 |

12 |

|

1123-1600 |

185 |

145 |

4 |

M16 |

18 |

12 |

|

1123-2500 |

185 |

145 |

8 |

M16 |

18 |

22 |

|

1123-4000 |

185 |

145 |

8 |

M16 |

18 |

22 |

|

Nominal Bore 80 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

190 |

150 |

4 |

M16 |

18 |

10 |

|

1123-1000 |

200 |

160 |

8 |

M16 |

18 |

12 |

|

1123-1600 |

200 |

160 |

8 |

M16 |

18 |

14 |

|

1123-2500 |

200 |

160 |

8 |

M16 |

18 |

22 |

|

1123-4000 |

200 |

160 |

8 |

M16 |

18 |

22 |

|

Nominal Bore100 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

210 |

170 |

4 |

M16 |

18 |

10 |

|

1123-1000 |

220 |

180 |

8 |

M16 |

18 |

12 |

|

1123-1600 |

220 |

180 |

8 |

M16 |

18 |

14 |

|

1123-2500 |

235 |

190 |

8 |

M20 |

22 |

25 |

|

1123-4000 |

235 |

190 |

8 |

M20 |

22 |

25 |

|

Nominal Bore150 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

240 |

200 |

8 |

M16 |

18 |

12 |

|

1123-1000 |

250 |

210 |

8 |

M16 |

18 |

14 |

|

1123-1600 |

250 |

210 |

8 |

M16 |

18 |

16 |

|

1123-2500 |

270 |

220 |

8 |

M24 |

26 |

28 |

|

1123-4000 |

270 |

220 |

8 |

M24 |

26 |

28 |

|

Nominal Bore200 |

Flange Diameter |

PCD |

Bolts |

Boltsize |

Hole Size |

Thickness |

|

1123-600 |

265 |

225 |

8 |

M16 |

18 |

12 |

|

1123-1000 |

285 |

240 |

8 |

M20 |

22 |

16 |

|

1123-1600 |

285 |

240 |

8 |

M20 |

22 |

18 |

|

1123-2500 |

300 |

250 |

8 |

M24 |

26 |

30 |

|

1123-4000 |

300 |

250 |

8 |

M24 |

26 |

30 |

SABS 1123 Class 600k Flange Dimensions:

|

NB |

Pipe Outside Dai. d1 |

Flange |

RF |

Bolt |

Drilling |

WN |

Boss |

|||||||||||

|

D |

b |

b1 |

b2 |

b3 |

h |

h1 |

d4 |

f |

No. |

d2 |

k |

d3 |

h2 |

r |

d5 |

|||

|

10 |

17.2 |

75 |

8 |

10 |

8 |

10 |

16 |

28 |

35 |

2 |

M10 |

4 |

11 |

50 |

26 |

6 |

4 |

25 |

|

15 |

21.3 |

80 |

8 |

10 |

8 |

10 |

16 |

30 |

40 |

2 |

M10 |

4 |

11 |

55 |

30 |

6 |

4 |

30 |

|

20 |

26.9 |

90 |

8 |

10 |

8 |

10 |

18 |

32 |

50 |

2 |

M10 |

4 |

11 |

65 |

38 |

6 |

4 |

40 |

|

25 |

33.7 |

100 |

8 |

10 |

8 |

10 |

18 |

35 |

60 |

2 |

M10 |

4 |

11 |

75 |

42 |

6 |

4 |

50 |

|

32 |

42.4 |

120 |

8 |

10 |

8 |

10 |

20 |

35 |

70 |

2 |

M12 |

4 |

14 |

90 |

55 |

6 |

6 |

60 |

|

40 |

48.3 |

130 |

8 |

10 |

8 |

10 |

20 |

38 |

80 |

3 |

M12 |

4 |

14 |

100 |

62 |

7 |

6 |

70 |

|

50 |

60.3 |

140 |

8 |

10 |

8 |

10 |

22 |

38 |

90 |

3 |

M12 |

4 |

14 |

110 |

74 |

8 |

6 |

80 |

|

65 |

76.1 |

160 |

8 |

10 |

8 |

10 |

26 |

38 |

110 |

3 |

M12 |

4 |

14 |

130 |

88 |

9 |

6 |

100 |

|

80 |

88.9 |

190 |

10 |

10 |

10 |

10 |

28 |

42 |

128 |

3 |

M16 |

4 |

18 |

150 |

102 |

10 |

8 |

110 |

|

100 |

114.3 |

210 |

10 |

10 |

10 |

10 |

34 |

45 |

148 |

3 |

M16 |

4 |

18 |

170 |

130 |

10 |

8 |

130 |

|

*125 |

139.7 |

240 |

13 |

12 |

13 |

12 |

39 |

48 |

178 |

3 |

M16 |

8 |

18 |

200 |

155 |

10 |

8 |

160 |

|

150 |

168.3 |

265 |

13 |

12 |

13 |

12 |

39 |

48 |

202 |

3 |

M16 |

8 |

18 |

225 |

184 |

12 |

10 |

185 |

|

*175 |

193.7 |

295 |

13 |

14 |

– |

14 |

– |

52 |

230 |

3 |

M16 |

8 |

18 |

255 |

210 |

12 |

10 |

– |

|

200 |

219.1 |

320 |

13 |

14 |

– |

14 |

– |

55 |

258 |

3 |

M16 |

8 |

18 |

280 |

236 |

15 |

10 |

– |

|

*225 |

244.5 |

345 |

16 |

16 |

– |

16 |

– |

58 |

285 |

3 |

M16 |

8 |

18 |

305 |

264 |

15 |

12 |

– |

|

250 |

273 |

375 |

16 |

16 |

– |

16 |

– |

60 |

312 |

3 |

M16 |

12 |

18 |

335 |

290 |

15 |

12 |

– |

|

300 |

323.9 |

440 |

20 |

20 |

– |

20 |

– |

62 |

365 |

4 |

M20 |

12 |

22 |

395 |

342 |

15 |

12 |

– |

|

350 |

355.6 |

490 |

22 |

22 |

– |

22 |

– |

62 |

415 |

4 |

M20 |

12 |

22 |

445 |

385 |

15 |

12 |

– |

|

400 |

406.4 |

540 |

22 |

22 |

– |

22 |

– |

65 |

465 |

4 |

M20 |

16 |

22 |

495 |

438 |

15 |

12 |

– |

|

450 |

457.2 |

595 |

24 |

25 |

– |

25 |

– |

65 |

520 |

4 |

M20 |

16 |

22 |

550 |

492 |

15 |

12 |

– |

|

500 |

508 |

645 |

24 |

25 |

– |

25 |

– |

68 |

570 |

4 |

M20 |

20 |

22 |

600 |

538 |

15 |

12 |

– |

|

550 |

559 |

705 |

24 |

28 |

– |

28 |

– |

68 |

620 |

5 |

M24 |

20 |

26 |

655 |

590 |

16 |

12 |

– |

|

600 |

609.6 |

755 |

24 |

30 |

– |

30 |

– |

70 |

670 |

5 |

M24 |

20 |

26 |

705 |

640 |

16 |

12 |

– |

Class 1000 SABS 1123 Flange Dimensions:

|

NB |

Pipe Outside Dai. d1 |

Flange |

RF |

Bolt |

Drilling |

WN |

Boss |

|||||||||||

|

D |

b |

b1 |

b2 |

b3 |

h |

h1 |

d4 |

f |

No. |

d2 |

k |

d3 |

h2 |

r |

d5 |

|||

|

10 |

17.2 |

90 |

8 |

10 |

8 |

10 |

14 |

35 |

40 |

2 |

M12 |

4 |

14 |

60 |

28 |

6 |

4 |

30 |

|

15 |

21.3 |

95 |

8 |

10 |

8 |

10 |

14 |

35 |

45 |

2 |

M12 |

4 |

14 |

65 |

32 |

6 |

4 |

35 |

|

20 |

26.9 |

105 |

8 |

10 |

8 |

10 |

16 |

38 |

58 |

2 |

M12 |

4 |

14 |

75 |

40 |

6 |

4 |

45 |

|

25 |

33.7 |

115 |

8 |

10 |

8 |

10 |

16 |

38 |

68 |

2 |

M12 |

4 |

14 |

85 |

46 |

6 |

4 |

52 |

|

32 |

42.4 |

140 |

10 |

10 |

10 |

10 |

20 |

40 |

78 |

2 |

M16 |

4 |

18 |

100 |

56 |

6 |

6 |

60 |

|

40 |

48.3 |

150 |

10 |

10 |

10 |

10 |

20 |

42 |

88 |

3 |

M16 |

4 |

18 |

110 |

64 |

7 |

6 |

70 |

|

50 |

60.3 |

165 |

12 |

10 |

10 |

12 |

20 |

45 |

102 |

3 |

M16 |

4 |

18 |

125 |

75 |

8 |

6 |

85 |

|

65 |

76.1 |

185 |

12 |

12 |

12 |

12 |

26 |

45 |

122 |

3 |

M16 |

4 |

18 |

145 |

90 |

10 |

6 |

105 |

|

80 |

88.9 |

200 |

14 |

12 |

12 |

14 |

26 |

50 |

138 |

3 |

M16 |

8 |

18 |

160 |

105 |

10 |

8 |

118 |

|

100 |

114.3 |

220 |

14 |

12 |

12 |

14 |

32 |

52 |

158 |

3 |

M16 |

8 |

18 |

180 |

131 |

12 |

8 |

140 |

|

*125 |

139.7 |

250 |

16 |

14 |

14 |

16 |

36 |

55 |

188 |

3 |

M16 |

8 |

18 |

210 |

156 |

12 |

8 |

168 |

|

150 |

168.3 |

285 |

18 |

16 |

16 |

18 |

38 |

55 |

212 |

3 |

M20 |

8 |

22 |

240 |

184 |

12 |

10 |

195 |

|

*175 |

193.7 |

315 |

18 |

16 |

18 |

60 |

242 |

3 |

M20 |

8 |

22 |

270 |

210 |

12 |

10 |

|||

|

200 |

219.1 |

340 |

18 |

18 |

18 |

62 |

268 |

3 |

M20 |

8 |

22 |

295 |

235 |

16 |

10 |

|||

|

*225 |

244.5 |

370 |

18 |

18 |

18 |

62 |

290 |

3 |

M20 |

8 |

22 |

325 |

265 |

16 |

10 |

|||

|

250 |

273.0 |

395 |

20 |

20 |

20 |

68 |

320 |

3 |

M20 |

12 |

22 |

350 |

292 |

16 |

12 |

|||

|

300 |

323.9 |

445 |

22 |

22 |

22 |

68 |

370 |

4 |

M20 |

12 |

22 |

400 |

344 |

16 |

12 |

|||

|

350 |

355.6 |

505 |

26 |

25 |

25 |

68 |

430 |

4 |

M20 |

16 |

22 |

460 |

385 |

16 |

12 |

|||

|

400 |

406.4 |

565 |

26 |

25 |

25 |

72 |

482 |

4 |

M24 |

16 |

26 |

515 |

400 |

16 |

12 |

|||

|

450 |

457.2 |

615 |

28 |

30 |

30 |

72 |

532 |

4 |

M24 |

20 |

26 |

565 |

492 |

16 |

12 |

|||

|

500 |

508.0 |

670 |

28 |

32 |

32 |

75 |

585 |

4 |

M24 |

20 |

26 |

620 |

542 |

16 |

12 |

|||

|

550 |

559.0 |

730 |

28 |

35 |

35 |

80 |

635 |

5 |

M24 |

20 |

26 |

675 |

592 |

18 |

12 |

|||

|

600 |

609.6 |

780 |

28 |

38 |

38 |

80 |

685 |

5 |

M24 |

20 |

26 |

725 |

642 |

|||||

Sabs 1123 Blind Flanges Maximum Weight:

|

Pipe Size |

Class 150 |

Class 300 |

Class 600 |

Class 900 |

Class 1500 |

Class 2500 |

||||||||||||

|

WN |

SO |

BLD |

WN |

SO |

BLD |

WN |

SO |

BLD |

WN |

SO |

BLD |

WN |

SO |

BLD |

WN |

SO |

BLD |

|

|

1/2″ |

2 |

1 |

1 |

2 |

1 |

1 |

2 |

2 |

2 |

1500# Weight |

5 |

4 |

4 |

7 |

7 |

7 |

||

|

3/4″ |

2 |

2 |

2 |

3 |

3 |

3 |

4 |

3 |

3 |

1500# Weight |

6 |

5 |

6 |

8 |

8 |

8 |

||

|

1″ |

3 |

2 |

2 |

4 |

3 |

3 |

4 |

4 |

4 |

1500# Weight |

9 |

8 |

8 |

12 |

11 |

11 |

||

|

1 1/2″ |

4 |

3 |

3 |

7 |

6 |

6 |

8 |

7 |

8 |

1500# Weight |

13 |

12 |

13 |

25 |

22 |

23 |

||

|

2″ |

6 |

5 |

5 |

9 |

7 |

8 |

12 |

9 |

10 |

1500# Weight |

25 |

25 |

25 |

42 |

37 |

39 |

||

|

2 1/2″ |

8 |

7 |

7 |

12 |

10 |

12 |

18 |

13 |

15 |

1500# Weight |

36 |

36 |

35 |

52 |

55 |

56 |

||

|

3″ |

10 |

8 |

9 |

15 |

13 |

16 |

23 |

16 |

20 |

31 |

26 |

29 |

48 |

48 |

48 |

94 |

83 |

86 |

|

4″ |

15 |

13 |

17 |

25 |

22 |

27 |

42 |

37 |

41 |

53 |

53 |

54 |

73 |

73 |

73 |

145 |

125 |

130 |

|

5″ |

19 |

15 |

20 |

32 |

28 |

35 |

68 |

63 |

68 |

86 |

83 |

87 |

130 |

130 |

140 |

245 |

210 |

225 |

|

6″ |

24 |

19 |

26 |

42 |

39 |

50 |

81 |

80 |

86 |

110 |

110 |

115 |

165 |

165 |

160 |

380 |

325 |

345 |

|

8″ |

39 |

30 |

45 |

67 |

58 |

81 |

120 |

115 |

140 |

175 |

170 |

200 |

275 |

260 |

300 |

580 |

485 |

530 |

|

10″ |

52 |

43 |

70 |

91 |

81 |

124 |

190 |

170 |

230 |

260 |

245 |

290 |

455 |

435 |

510 |

1075 |

930 |

1025 |

|

12″ |

80 |

64 |

110 |

140 |

115 |

185 |

225 |

200 |

295 |

325 |

325 |

415 |

690 |

580 |

690 |

1525 |

1100 |

1300 |

|

14″ |

110 |

90 |

140 |

180 |

165 |

250 |

280 |

230 |

355 |

400 |

400 |

520 |

940 |

NA |

975 |

NA |

NA |

NA |

|

16″ |

140 |

98 |

180 |

250 |

190 |

295 |

390 |

330 |

495 |

495 |

425 |

600 |

1250 |

NA |

1300 |

NA |

NA |

NA |

|

18″ |

150 |

130 |

220 |

320 |

250 |

395 |

475 |

400 |

630 |

680 |

600 |

850 |

1625 |

NA |

1750 |

NA |

NA |

NA |

|

20″ |

180 |

165 |

285 |

400 |

315 |

505 |

590 |

510 |

810 |

830 |

730 |

1075 |

2050 |

NA |

2225 |

NA |

NA |

NA |

|

22″ |

225 |

185 |

355 |

465 |

370 |

640 |

720 |

590 |

1000 |

NA |

NA |

NA |

NA |

NA |

NA |

NA |

NA |

NA |

|

24″ |

260 |

220 |

430 |

580 |

475 |

790 |

830 |

730 |

1250 |

1500 |

1400 |

2025 |

3325 |

NA |

3625 |

NA |

NA |

NA |

1123 Sabs Flange Material Pressure Rating Table:

|

Temperature |

||||||||

|

Flanges Tables |

-10°C to 200°C |

250°C |

300°C |

350°C |

400°C |

425°C |

450°C |

475°C |

|

6 |

6 |

5.5 |

5 |

– |

– |

– |

– |

– |

|

10 |

10 |

9 |

8 |

7 |

6 |

– |

– |

– |

|

16 |

16 |

15 |

13 |

11 |

9 |

– |

– |

– |

|

25 |

25 |

24 |

21 |

17 |

14 |

12 |

9 |

6 |

|

40 |

40 |

38 |

33 |

28 |

23 |

20 |

15 |

10 |

|

64 |

64 |

61 |

53 |

44 |

36 |

32 |

24 |

16 |

|

100 |

100 |

95 |

83 |

70 |

57 |

50 |

37 |

25 |

|

160 |

160 |

152 |

132 |

112 |

92 |

80 |

60 |

40 |

Sabs 1123 Pipe Flanges Application Industries:

- Seawater Cooling Devices

- Architectural railings

- Wiring In Electrostatic Precipitators

- Oil Refinery

- Gas Scrubbing Plants

- Pulp and Paper Processing Industries

- Acetic, Phosphoric and Sulphuric Acid Processing Plants