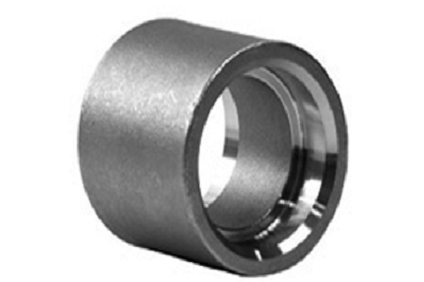

ASME B16.11 Fitting

Specification

CHEMICAL & MECHANICAL COMPOSITION

Enquire Now

Forged Steel Fittings Socket Weld and Threaded Fittings Manufacturer in India.

Check Stainless Steel Threaded Pipe Fittings Pressure Rating And Class 3000 Socket Weld Fittings Dimensions Chart, ASME B16.11 Forged Fittings Weight Chart In Inch.

Detailed Information

Prashaant Steel & Alloys is well-known on the international market and is eager to include high-quality ASME B16.11 Fittings. Prashaant Steel & Alloys is a producer, supplier, stockiest, and exporter of ASME B16.11 Fittings, and exports the material to global customers at reasonable prices. ASME B16.11 Fittings are made in line with established manufacturing practises, allowing for the most effective use of raw materials. We market ASME B16.11 Fittings in custom thicknesses and styles to suit the needs of our customers. The bars are made under the close guidance of a knowledgeable team with considerable expertise in the industry. We also allow the use of modern equipment and cutting-edge technology, allowing Prashaant Steel & Alloys to achieve better results. Many quality standards for raw materials are also used to achieve production. The role of the quality control department in ensuring product quality is assuring in providing commendable product continuity. A number of raw material quality requirements are also taken into account during processing. The Quality Control Department’s role in ensuring product quality is to achieve reliable, commendable outcomes.

Most manufacturers use standard ASME B16.11 in order to produce Forged, Socket-Welding and Threaded Steel Fitting. The standard acts as a reference point for manufacturers by providing details for the production of ASME B16.11 Fittings such as ratings, dimensions, tolerances, marking and material requirements. Threaded fitting is one of the oldest methods of joining. These fittings are used in applications which pose a fire hazard. Or the 3000# Threaded Pipe Fitting Dimensions could also be used in those places where welding is not feasible on account of space constraints or if they get flammable. The Stainless Steel Threaded Pipe Fitting provides for an easy and speedy connection since the threads on the fitting and the pipe are intended to hold the piping system together.

Although the use of the material is based on the application it is to cater to. For instance, if an application requires good tensile strength in addition to hardness and toughness, while corrosion resistance is not considered to be an important property, Carbon Steel Socket Weld Fitting is preferred. This is because these fittings are inexpensive and are easily available. Industries that make use of the Socket Weld Pipe Fitting Weight Chart include Chemical Industries, Machines and equipment, Power stations, Water treatment systems, Sanitary tubing, Heat Exchangers, Oil and gas transmissions as well as petroleum and Oil refining.

Forged Socket Weld Fittings Specification:

|

Specification : |

ASME B16.11 Fittings |

|

Dimensions Class: |

2000#, 3000#, 6000#, 9000# |

|

Pressure: |

Check Pressure Rating Of Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

|

Size Chart Of: |

1/8” NB to 4” NB (Screwed-Socket) |

|

Standard Of: |

JISB2311, IS 2062, DIN, ANSI B16.28, ASME B16.9, BS10, ASME B16.47, ASME B16.38, MSS-SP-43, JISB2313, ASME B16.25, MSS SP-75, DIN2605, JISB2312, PN, AWWA C207, BS4504, BS1560, BS, GB, ISO |

|

ASME B16.11 Fittings Connection Type : |

Welding |

|

Forged Type : |

NPT (Threaded), BSPT, BSPP. |

SW Fitting ASME B16.11 Weight Chart:

|

Pipe Size |

A |

B |

QTY |

Weight Chart |

|

¼ |

0.81 |

0.88 |

160 |

0.20 |

|

⁄ |

0.97 |

1.00 |

130 |

0.26 |

|

½ |

1.12 |

1.31 |

100 |

0.57 |

|

¾ |

1.31 |

1.5 |

75 |

0.71 |

|

1 |

1.5 |

1.81 |

40 |

1.08 |

|

1 ¼ |

1.75 |

2.19 |

25 |

1.68 |

|

1 ½ |

2.00 |

2.44 |

18 |

2.38 |

|

2 |

2.38 |

2.97 |

10 |

3.55 |

|

2 ½ |

3.00 |

3.62 |

4 |

6.22 |

|

3 |

3.38 |

4.31 |

2 |

10.36 |

|

4 |

4.19 |

5.75 |

1 |

23.91 |

NPT Pipe Fitting Weight Size:

|

Pipe Size |

A |

B |

QTY |

Weight Chart |

|

¼ |

0.81 |

0.88 |

160 |

0.20 |

|

⁄ |

0.97 |

1.00 |

130 |

0.26 |

|

½ |

1.12 |

1.31 |

100 |

0.57 |

|

¾ |

1.31 |

1.5 |

75 |

0.71 |

|

1 |

1.5 |

1.81 |

40 |

1.08 |

|

1 ¼ |

1.75 |

2.19 |

25 |

1.68 |

|

1 ½ |

2.00 |

2.44 |

18 |

2.38 |

|

2 |

2.38 |

2.97 |

10 |

3.55 |

|

2 ½ |

3.00 |

3.62 |

4 |

6.22 |

|

3 |

3.38 |

4.31 |

2 |

10.36 |

|

4 |

4.19 |

5.75 |

1 |

23.91 |

ASME B16.11 Threaded Fittings Size Chart:

|

NPS |

Minimum Length of Thread |

OD of Band D |

Center to End A |

Minimum Wall Thick. |

|

|

B |

J |

||||

|

1/2 |

10.9 |

13.6 |

33 |

28 |

3.18 |

|

3/4 |

12.7 |

13.9 |

38 |

33 |

3.18 |

|

1 |

14.7 |

17.3 |

46 |

38 |

3.68 |

|

1 ¼ |

17 |

18 |

56 |

44 |

3.89 |

|

1 ½ |

17.8 |

18.4 |

62 |

51 |

4.01 |

|

2 |

19 |

19.2 |

75 |

60 |

4.27 |

|

2 ½ |

23.6 |

28.9 |

92 |

76 |

5.61 |

|

3 |

25.9 |

30.5 |

109 |

86 |

5.99 |

|

4 |

27.7 |

33 |

146 |

106 |

6.55 |

Stainless Steel Threaded Fitting Pressure Rating:

|

Pressure for ASME B16.11 Fittings (psig) |

|||||

|

Temperature |

Class |

||||

|

150LB |

300LB |

||||

|

1/4 – 1 in. |

1 1/4 – 2 in. |

2 1/2 – 3 in. |

|||

|

(oF) |

(oC) |

||||

|

-20 to 150 |

-29 to 66 |

300 |

2000 |

1500 |

1000 |

|

200 |

93 |

265 |

1785 |

1350 |

910 |

|

250 |

121 |

225 |

1575 |

1200 |

825 |

|

300 |

149 |

185 |

1360 |

1050 |

735 |

|

350 |

177 |

150 |

1150 |

900 |

650 |

|

400 |

204 |

– |

935 |

750 |

560 |

|

450 |

232 |

– |

725 |

600 |

475 |

|

500 |

260 |

– |

510 |

450 |

385 |

|

550 |

288 |

– |

300 |

300 |

300 |